How to Test 3 Wire Crank Sensor With Multimeter?

A 3 wire crank sensor is an integral part of the crankshaft. It works as a multifunctional device that can detect the engine RPM and the speed related to it along with setting the timing of the ignition. A bad sensor can stall the acceleration, create engine resistance, increase fuel consumption, and cause sudden RPM drops. To find out if the device is at fault, you need to learn how to test 3 wire crank sensor with multimeter.

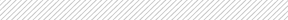

With a functioning 3 wire crank sensor, a car can calculate how efficiently it’s performing with regards to gas mileage, power output, and emissions production. If you’re looking for a new or used car, this information can be useful in determining whether an automobile will meet your needs before you buy it.

How to Test 3 Wire Crank Sensor with Multimeter

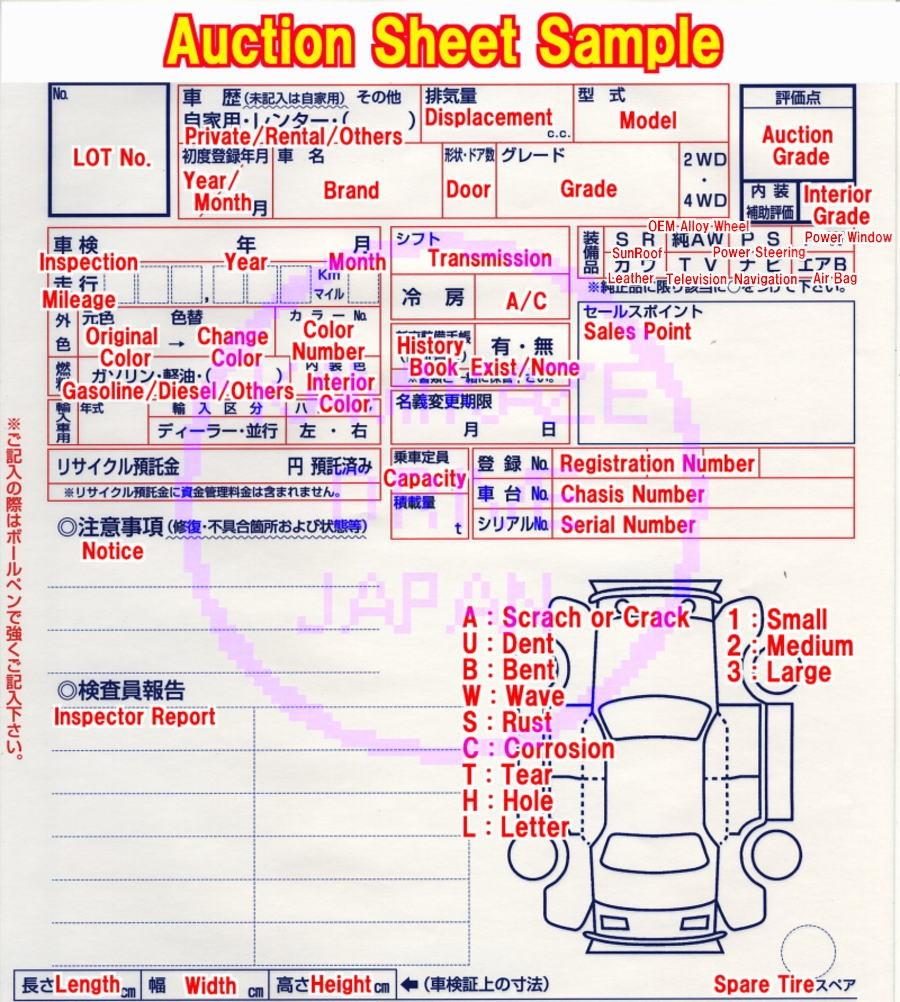

The most common symptom of a defective crank sensor is the turning on of the check engine light. In addition, you may encounter various engine problems along with unusually high fuel consumption. Sometimes, the engine may not even start at all and it can lead to a total engine failure.

If you are facing these problems, you should examine the 3 wire crank sensor. Follow these steps to check the health of the crankshaft position sensor.

Find the Position of the Wires

Refer to the owner’s manual to find out the power, ground, and signal wires. Now, prepare the multimeter for examining the 3 wire sensor. For testing the sensor’s circuit, you need to set it to DC volt.

Touch the Wires

Make sure that the car engine is turned off. Turn on the ignition key. Then, take the black multimeter cable and touch it to the ground wire. Similarly, touch the other multimeter cable to the power wire.

Look into the Readings

Look into the multimeter readings and note them down. Now, take the owner’s manual and compare the data with the figures given there.

Touch the Wires Again

Ask someone to start the engine and then touch the multimeter’s black cable to the ground wire and red cable to the signal wire.

Take the Readings Again

Note down the readings again and compare the figures against the ones stated in the manual.

SEE MORE

Interpret the Data

If the readings on the multimeter are lower than the figures specified in the manual, the 3 wire sensor is likely to be defective. You can draw the same conclusion if there is no signal at all on the multimeter.

A 3 wire crankshaft position sensor can wear out or fail over time. If it fails the multimeter test, you should replace it with a new one.

Conclusion

When you are experiencing some specific problems with your car’s acceleration, performance, or engine, the trouble might be with the car’s crank sensor. To find out if the sensor is faulty, you have to test it with a multimeter. Use this guide to learn how to test 3 wire crank sensor with multimeter, and save yourself a trip to the mechanic!