The crankshaft position sensor, in case you don’t know, is an electronic device that is vital to the functioning of a car. It is located in the engine of the car. It registers the rate of spinning of the crankshaft.

This sensor then passes the information to the ECU and decides optimal fuel injection and regulation of ignition.

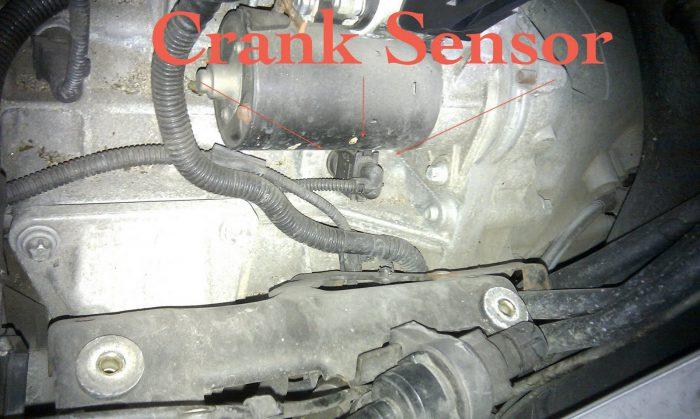

It is the location of the crankshaft that determines the effectiveness of the gathered data.This is why the sensor is located either next to the camshaft or the crankshaft itself.

If we try to explain it in simpler words, the crankshaft position sensor monitors within the engine the location of the camshaft.

The information that it gathers thus, it uses the same to optimize the timing of fuel injection in the engine.

In case this sensor malfunctions, the computer will be unable to make fine adjustments to fuel injection and the performance of the engine will dip.

Contents

How Does the Crankshaft Position Sensor Work?

Here are a few ways in which this sensor functions. Let’s take a look.

Sensing

If you look at the crankshaft, you will find a powerful magnet next to it. You will also find that there are steel pins or pegs arranged at regular intervals around the crankshaft.

This magnet constantly radiates a magnetic field that is steady. As the engine starts and the crankshaft spins the steel pins around the shaft rotate around this field. This causes fluctuation in the field, thus producing an AC (alternating current) signal.

This further signals the engine management unit (engine computer) to decipher the speed of rotation. In turn, the EMU is able to calculate the position and the pace of the camshaft to further optimize fuel injection and ignition.

Adjustments

The way modern cars are, we must learn one thing. The engines will give us an efficient performance only if the internal parts are moving at a particular recommended speed.

It is only once the crankshaft position sensor senses the rotation of the crankshaft inside the engine that the on-board can make use of the information that the sensor sends to it.

This is when the computer will make small adjustments/fine-tunings into the engine to increase its efficiency.

Consider the cases when you are moving full-throttle. The constant throttle in modes like cruise mode or sports mode, the computer needs to make these fine adjustments to the engine in order to change the speed.

The computer will ensure that it constantly checks the rotational speed of the crankshaft, compares it to the ideal range, and makes speed adjustments accordingly. This adjustment can be in terms of both increasing and decreasing the speed.

SEE MORE

- Why does Your Car Engine Fail to Start?

- What’s the Greatest Damage when an Accidental Car Runs out of Fuel?

What Happens When The Crankshaft Position Sensor Malfunctions?

If you need to keep your engine performing well, it is imperative that this sensor stays in top condition. Any defect in the sensor will result in the communication of incorrect data to the engine management unit.

The engine, when performing on the basis of this data will not perform optimally. It may even go as bad as making the car stall.

The reason is that the EMU will start depending on its own memory to ensure fueling and ignition, which by the way, cannot be optimal.

So, diminished engine performance could actually be one of the symptoms of crankshaft sensor failure.

FAQs on The Crankshaft Position Sensor Function

-

Can a bad CKP sensor cause engine damage?

While a faulty CKP sensor can cause poor engine performance and drivability issues, it typically doesn’t directly cause engine damage.

However, continued operation with a malfunctioning CKP sensor can lead to other problems, so it’s crucial to address the issue promptly.

-

How is a faulty crankshaft position sensor diagnosed and repaired?

Diagnosing a faulty CKP sensor involves using a scan tool to read diagnostic trouble codes (DTCs) from the ECM.

Additionally, technicians may perform electrical tests and inspect the sensor and its wiring.

If a fault is confirmed, the sensor should be replaced with a new one, followed by clearing any DTCs.

-

Can I replace the crankshaft position sensor myself?

Replacing a CKP sensor can be a DIY task for those with mechanical skills and the necessary tools.

However, it’s essential to consult the vehicle’s service manual for specific instructions and ensure proper installation and torque specifications.

-

How often should a crankshaft position sensor be replaced?

There is no specific maintenance interval for CKP sensor replacement. It is generally replaced when it fails or exhibits symptoms of failure.

Regular vehicle maintenance and prompt sensor replacement when issues arise can help ensure optimal engine performance.

-

Are there different types of crankshaft position sensors?

Yes, there are different types of CKP sensors, including Hall-effect sensors and magnetic reluctor sensors. The type used depends on the vehicle’s make and model.

-

Can a damaged CKP sensor affect the vehicle’s emissions?

Yes, a malfunctioning CKP sensor can impact emissions by causing incomplete combustion and increased emissions of pollutants. Addressing CKP sensor issues can help maintain compliance with emission standards.

-

Can a faulty crankshaft position sensor cause the vehicle to suddenly stall while driving?

Yes, a malfunctioning CKP sensor can lead to sudden stalling while driving. If the sensor fails to provide accurate data to the ECM, it can disrupt the engine’s ignition timing and fuel injection, causing the engine to shut down unexpectedly.

-

Is the crankshaft position sensor the same as the camshaft position sensor?

No, the crankshaft position sensor (CKP sensor) and the camshaft position sensor (CMP sensor) are not the same. While both sensors provide critical data to the ECM for engine control, they monitor different components.

The CKP sensor monitors the crankshaft’s position and rotational speed, while the CMP sensor monitors the camshaft’s position and timing.

Check out this video from Easy Auto Fix to learn more about the bad rankshaft position sensor!

In general, the crankshaft position sensor plays a very important role in ensuring the performance of the engine and adding to its efficiency. Follow the maintenance tips recommended by your automaker to keep it in a great shape.