Car brakes are constantly being improved to enhance the safety features of the vehicle. This is one of the indispensable systems of automobiles that manufacturers invest in and develop. Drivers can be confident on every journey when the brakes operate smoothly and efficiently. Cars with modern brake systems often have more competitive advantages in the market. So in this article, Car From Japan will give you information about 5 types of car brakes that are commonly used in modern cars.

Contents

5 Types of Car Brakes are Commonly Used in Present Automobiles.

Brakes are mechanical devices that limit wheel movement by creating friction. Accordingly, the brakes for a car when operating will help control the speed or stop the vehicle at the discretion of the driver. In the early development of cars, brakes were just logs attached to the rims of a carriage. The driver pushes the lever, the wooden block will limit the rotation speed of the wheel. Later, to reduce heaviness, the wooden brake system was replaced with steel and leather.

However, they still do not provide the desired braking effect and cause annoying noises. The problem poses for car manufacturers is the need to improve the brake system to ensure safety, high aesthetics, and bring comfort to the driver. Up to now, modern cars are equipped with advanced brake systems to enhance safety for use.

For every car brakes type, there will be certain pros and cons. Therefore, to evaluate and compare which system is better, we must base on their advantages and disadvantages and compare them with our needs and control habits to choose the right type of brakes. Let’s find out in detail about the features of these different types of brakes in the next part of the article.

Drum brakes

The drum brake is commonly used on two-wheeled or four-wheeled cars. Drum brakes on cars often use hydraulic brakes because they use hydraulic pressure to push on the brake pads. When the driver hits the brake pedal, pressure presses two brake shoes against the drum. It will make friction and causes your car to slow and stop. Drum brakes include many components such as brake shoes, brake pads, pads, springs, brake drums, etc., which take on different roles in the brake system.

- Brake shoes: Made of die-cast aluminum, featuring light-weight and good heat dissipation. Brake shoes have many different designs and are made specifically for each model, and year of manufacture. They are usually shaped like a circle with two semicircular toes. This component is located in a part of the drum brake, but the brake shoe will not touch or come into direct contact with the drum.

- Wheel cylinder: Function as a chamber containing piston, and oil to transmit fluid pressure into mechanical motion.

- Return Spring: When the oil pressure decreases, the return spring will force the piston back to its original position.

- Piston: The part that is connected to the brake shoe. When there is oil pressure, this part will push out, causing pads to press against the brake drum to help the vehicle stop.

Pros:

- High durability, adapt to many different weather and terrain conditions thanks to the sealed design, avoiding environmental factors such as dirt.

- Save on maintenance, replacement, and installation costs.

- The brake drum has a simple structure, so it is easy to disassemble. And, the cost is low.

- Make sure the necessary safety, the car does not slip when braking.

Cons:

- Compared to disc brakes, drum brakes have more weight and a slower deceleration time.

- The sealed design makes the ability to diffuse heat poorly, reducing braking performance, especially in the case of urgent braking.

>> Related post: How to Change Drum Brakes In a Few Steps

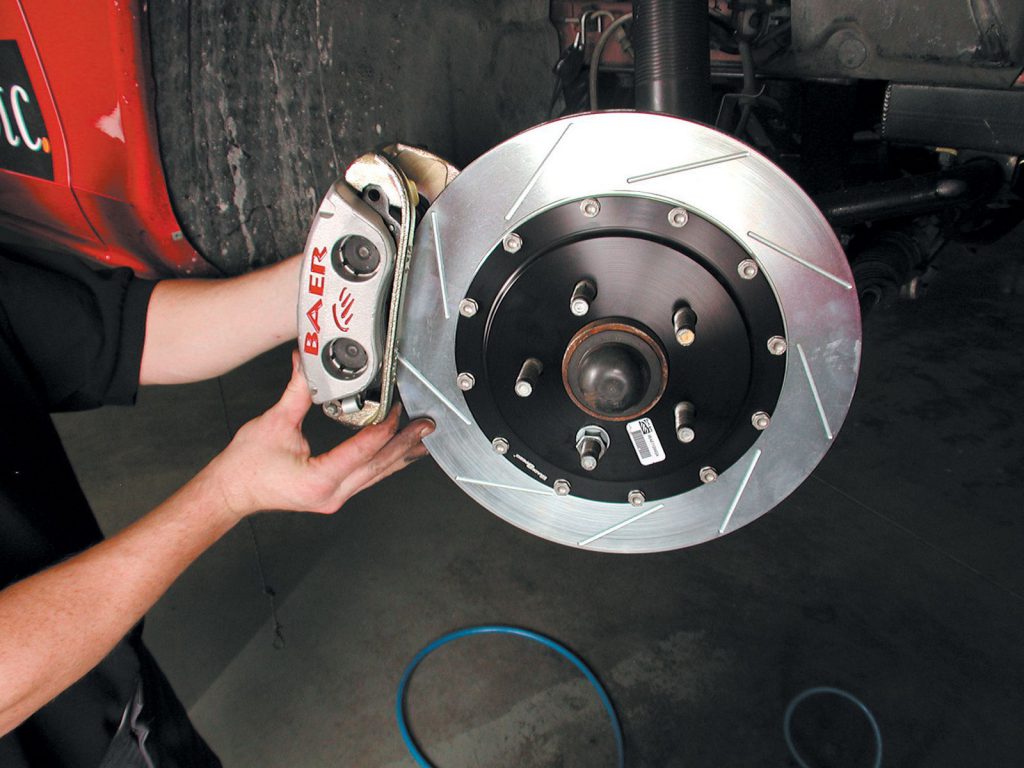

Disc brakes

Possessing many outstanding advantages compared to drum brakes, disc brakes are equipped on the front wheels of many commercial cars. When drivers press the brake pedal, the oil pressure in the line and cylinder of the wheel will increase, pushing the piston and brake pads against the brake disc, creating friction and causing the wheel to slow down.

So how is its structure? A disc brake consists of 4 main parts: roto, caliper, pad, and piston. This brake combination is designed to be open, and the components have flexible coordination, helping the car to stop or reduce speed effectively.

- Roto: Most rotors today are made from carbon steel. This is a material with good heat resistance, good bearing capacity, and high durability.

- Caliper: Has the effect of holding and squeezing the brake pads against the brake disc to generate enough braking force to help the vehicle decelerate and stop without jerking.

- Brake pad: Brake pads are a unified block made from heat-resistant materials such as ceramic, metallic, and organic pads. This part of the car disc brake structure consists of 2 clamps that grip the brake disc.

- Piston: The principle of operation of disc brakes is to use specialized fluid to transmit force. When the piston is in operation, it puts pressure on the brake pads against the brake disc, helping the vehicle to slow down or stop

In addition to the above 4 main parts, disc brakes also have springs and air filters to help the disc brake system operate smoothly and efficiently. Along with using disc brakes on modern cars, most automakers equip optimal brake support technology such as anti-lock braking systems and brake force support systems.

Pros:

- The deceleration efficiency is much higher than that of drum brakes because of the greater frictional force.

- The material is heat resistant, good bearing, durable, less prone to damage, and weight is lighter than drum brakes.

- Disc brakes have an open structure to increase heat dissipation and water drainage. From that, the performance is improved, and technicians can easily observe the faults for cleaning and repair.

Cons:

- Because the disc brake is designed to be exposed, it is easy to stick to dust, reducing the efficiency after a long time of use. Therefore, drivers need to pay attention to cleaning or regularly taking them for maintenance to avoid damage to these parts.

- The friction between pads and discs can cause noise when driving the vehicle.

- Disc brakes are made from high-quality materials to help ensure vehicle safety. However, the cost of maintenance and replacement of disc brakes is much higher than that of drum brakes.

Emergency brakes

The emergency brake, also known as the parking brake, is mechanically operated and is used to keep the vehicle stay when parking. Even if the vehicle is parked on different slopes.

Where there is poor friction between the tire and the road surface, the parking brake will keep the wheels from moving. Based on the driving factor and how to control it, the handbrake is divided into two types: mechanical and electronic. Each type has a different structure, operating principle, and application.

>> Read more: Parking Brake Or Emergency Brake Does Not Work? Know the Troubleshooting Process Here

Mechanical handbrakes

They consist of a cable connected to the 2 rear wheels. When the driver pulls on the brake, the cable acts on the rotary lever, turning the traction force into pressing the brake shoes into the drum, limiting the rotation of the wheel to help your car stop. If the rear wheel uses a disc brake, the mechanical handbrake will use this mechanism to stop the vehicle.

Pros:

- Low production cost due to simple design

- Easy to disassemble, repair when broken

- The lifespan of components is longer than electronic brakes.

Cons:

- Takes up a large area of the car due to its bulky structure

- Many details and manipulations make it difficult for the driver to use

- Cost too much for periodic maintenance to avoid brake lock.

Electronic handbrake

The electronic handbrake was invented later, possessing outstanding and more modern advantages, so it is popularly used. It has a structure consisting of a DC motor actuator mounted on the two rear wheels and an EPB (Electronic Parking Brake). The operation of the electronic handbrake is handled by the electric motor. When pulling the brake, the electric signal is transmitted to the electric motor on the rear wheels through the EPB to help the vehicle stop. Drivers should pay attention to stepping on the front foot brake, then pull the control lever to activate the brake.

Pros:

- Compact design saves a lot of space for the car.

- Simple operation with a modern structure.

- Avoid unnecessary accidents when the driver forgets to release the brake.

- Limiting the situation of locking, brake jam occurs in mechanical brakes.

Cons:

- When out of the battery, the handbrake can’t work

- The brake pedal has a slight vibration when moving

- The lifespan of components is lower

Anti-Lock Brakes (ABS)

ABS brake system is an active safety system common on most cars today. This system works to slow down, stop and park the car in case of need. When the car brakes suddenly on a slippery road, the phenomenon of wheel locking is easy to occur. This causes the wheel to slide on the road when braking, endangering drivers. Anti-lock brakes were developed to solve this problem. ABS works to reduce the risk of accidents through optimal braking control. The ABS brake system on a car is made up of parts: a speed sensor, hydraulic valve, and control system.

- Speed sensor: The part that helps the ABS system to detect whether the wheels are locked or not. These speed sensors are placed on each wheel or differential.

- Hydraulic valve: A valve that controls the brake pads at each wheel. It will be located in 3 basic positions. Open valve (how much force the driver applies, the brake pressure will create the equivalent force directly transmitted to the wheel). Lock valve (brake pressure received more than the force applied by the driver). Release valve (brake pressure received is less than the force applied by the driver).

- Control system: Receive the task of collecting information and data from speed sensors, then calculate and make appropriate adjustments about the optimal brake pressure for each wheel.

Pros:

- Cars equipped with an anti-lock system will especially work when braking on slippery roads or when braking urgently, ensuring the stability of the car during braking, giving the driver more time to handle the situation, and protecting drivers.

- Optimize the space inside the cockpit, saving space.

- The operations are also simpler and more convenient.

Cons:

- Many people mistakenly believe that the main effect of ABS is to reduce braking distance. Reality is not like that.

- Higher production and repair costs due to modern technology and more complex features.

- Studies have also shown that ABS is not really effective on dry roads and has longer braking distances on snow

Regenerative Braking System (BRS)

Regenerative braking is one of the modern technologies in the automotive industry. Which are used in electric and hybrid vehicles, as well as in some gasoline vehicles. BRS converts kinetic energy into electric energy for cars, helping to increase fuel efficiency. On traditional car models, a large amount of energy is wasted if conventional braking is used. Because if the driver presses the brake pedal while the vehicle is moving. The braking surface is pushed back by friction from the drum or brake pads and completely wastes heat.

When braking in a hybrid or EV, the electric motor switches to generator mode. The wheels transmit kinetic energy through the transmission to the “generator”. The generator converts a large part of kinetic energy into electrical energy, which is then stored in a vehicle’s high-voltage battery. At the same time, the generator resistance in the process of generating electricity will slow down the vehicle.

Of course, this braking process takes a long time until the car stops. So when more braking torque is needed than the generator can provide. Additionally, braking is accomplished by friction.

Pros:

- Increase fuel efficiency: Reduced fuel consumption and CO2 emissions – especially in urban traffic situations involving frequent braking and acceleration

- Reduce wear and tear: In regenerative braking, when the motor is no longer receiving power from the battery pack, it re-spins the wheel rotation, utilizing mechanical energy and restoring energy to the storage battery. Therefore, reducing wear and prolonging the lifespan of the brakes is obvious.

- Not wasted much heat: Traditional braking systems apply friction to convert mechanical energy into heat. Therefore, from an energy perspective, braking generates an amount of heat that cannot be reused. However, regenerative braking slows the vehicle down in a very different way.

- Energy conservation: The flywheel absorbs energy when braking through a clutch system that reduces vehicle speed and increases wheel rotation. For acceleration, another clutch system links the flywheel to the drivetrain, increasing vehicle speed and reducing the flywheel. Thus, energy is conserved by heat and light – which often occurs in the braking system at the same time.

Cons:

- Only effective in the case of deceleration at very low speeds. Because the braking torque generated by the generator is not enough to stop the vehicle in a short time.

- The regenerative braking system has its own advantages when the car moves into the city. However, the vehicle’s fuel consumption is still higher when driving on the highway.

>> Read more: How To Choose Good Brake Pads For Your Car?

In Conclusion

The above is a summary of types of car brakes and things to know about car brakes so that drivers can refer to brake system maintenance and supplement their knowledge of using vehicles. Please always update the latest information from Car From Japan for safe and enjoyable driving.