A flywheel is a machine that reserves rotational energy by resisting changes in rotation speed. The stored energy is proportionate to the square of the speed of the rotation. You can change the machine’s preserved power by applying torque to grow or reduce its rotational speed. A machine or a vehicle loses momentum every time it slows down or stops. A flywheel makes up for that lost momentum by supplying its reserved power. In this brief guide, we will discuss how does a flywheel work and what does it.

Contents

What Is Flywheel On A Car?

A flywheel is a weighty wheel that requires plenty of force to rotate on its axis. When the wheel is in motion at a high speed, it will keep spinning unless you stop it by applying lots of force. When it rotates, it preserves a great amount of kinetic energy that it later uses to power up a vehicle or machine at the time of starting the engine or speeding up.

What is a flywheel on a car? Technically explained, the flywheel (if manual) or flex plate (if automatic transmission) is defined as a disc that is bolted to the crankshaft at the rear of the engine. It serves many purposes:

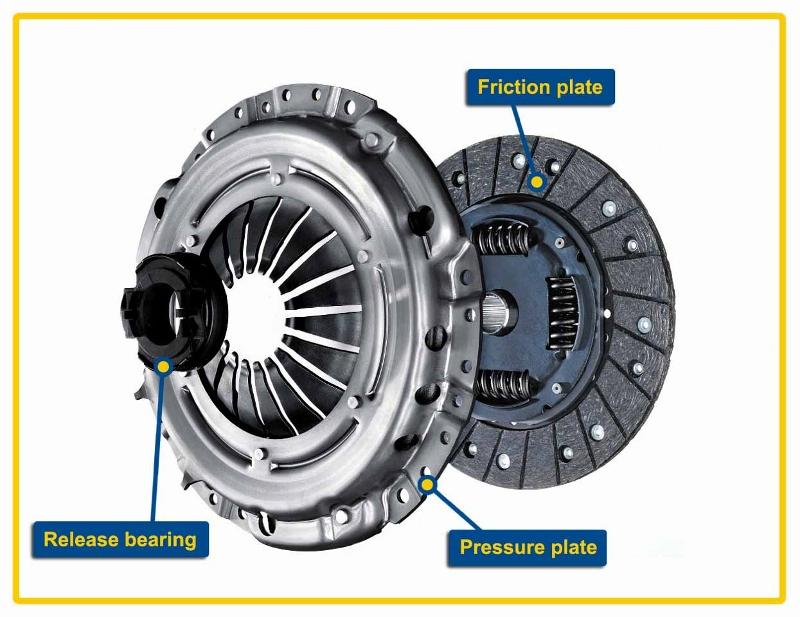

- On a manual transmission car, it gives one of the friction surfaces for the clutch. The clutch pressure plate is bolted to it and the clutch disk is sandwiched between them.

- On an automatic transmission car, it is actually known as a flex plate, and the torque converter of the transmission bolts to it.

There is a toothed ring on its outer edge that the starter turns to start the engine. Because of the large disc (relative to the crankshaft), this allows the starter motor to have more leverage against the engine.

It also serves to perform certain goals of engine operation. Though more massive flywheels require more energy to get spinning, once they are spinning they gain more momentum and help the engine run smoother and shift smoother at higher RPM.

Watch more:

How Does A Flywheel Work?

How does a flywheel work for storing the energy? Well, you can compare it to the mechanism of a mechanical battery. Whereas the battery stores the energy in a chemical form, a flywheel preserves the power in the form of movement or kinetic energy to be precise.

A flywheel will be able to store more energy if it spins at a higher speed or has a higher moment of inertia, which means bulkier. However, it always works best when you spin it faster rather than increasing its mass. For example, a wheel will produce twice as much energy than the one that weighs half of it, given that both are spun at the same speed. On the other hand, spinning the lighter wheel twice as fast will quadruple the amount of stored energy.

Read more:

For this reason, it’s always better to use lighter, high-speed wheels rather than the units having a massive weight. Also, compact flywheels make practical sense in racing cars because they need to be as light as possible to run at high speeds.

How does a flywheel work when you keep increasing the speed? It is not possible because there is a point when the wheel material won’t be able to handle the force and smash into fragments.

What Are The Functions Of A Flywheel?

Before delving into the working principle of flywheels for cars, it’s important to know their functions. It is used in almost all types of automobiles including race cars, trains, and buses. In the past, they used to have a large diameter with spokes and a bulky metal rim. However, the modern units are more compact due to being made of composite or carbon fiber materials. You have to push the wheel hard to set it in motion. It mainly serves these functions in most vehicles:

1. Engine start

The gear teeth cut into the flywheel’s circumference support starting the engine. In the engine’s starter motor, a small gear (called a Bendix gear) mates up to the flywheel when you turn the key. The Bendix gear/starter motor combination spins the flywheel, turning the crankshaft and beginning the compression cycle required to start the engine. After the engine starts, the Bendix gear withdraws to let the flywheel spin freely.

2. Engine speed smoothing

Once the engine has started, the crankshaft converts the up-and-down movement of the pistons into rotary motion. Nonetheless, this motion is jerky as power is generated only twice (for a four-cylinder engine) or four times (for an eight-cylinder) during one engine revolution. The mass of the flywheel applies inertia to keep the engine crankshaft turning between each of these piston firings, so the rotation speed of the crankshaft is kept constant and the engine runs smoothly.

3. Engine balancing

Since the pistons are offset from the center of the crankshaft, the engine consequently vibrates and wobbles as each piston fires at a different angle. The heavy weight of the flywheel suppresses this side-to-side motion, helping to stabilize and balance the engine on its mounts and reduce vibration throughout the vehicle.

4. Drivetrain stress reduction

By stabilizing the engine’s movement and smoothing out its speed, the flywheel limits wear and tear on other drivetrain components. Although the engine and the transmission shafts are parallel to each other, the attachments between the axle and the transmission are not; the driveshaft uses universal joints that constantly change angles as they turn. Flywheels help reduce the wear on such joints.

5. Weight manipulation

Flywheel weight is one of the adjustments that custom engine builders use to tailor their engine’s performance for specific purposes.

- Heavier flywheels allow engines to work under loads that may cause the engine to bog down; thus cars consistently pulling heavy trailers should benefit from a larger flywheel.

- Engines that run at high speeds—like race car engines—benefit from a lighter flywheel for better acceleration at speed; which can make it harder to keep the engine idling smoothly and more difficult to accelerate from a dead stop. Because of this, racers need their pit crews to push them to help start their cars.

Top 5 Bad Flywheel Symptoms

1. Burning smell

This smell is generated when the clutch is being used improperly, whether from a bad flywheel or an inexperienced driver. Clutches’ facings have materials intended to reduce the amount of noise the clutch makes during operation. The facings of the clutch produce a lot of heat due to friction from improper use which essentially makes the surface glaze over from the heat. The consequence is a strong pungent, acrid smell that can become quite noticeable.

2. Clutch chatter

Instead of smoothly engaging, the clutch “skips” along the flywheel. The clutch repeatedly grabs and releases which feels like a stutter or vibration when the clutch is released. While it can happen in any gear, it’s most popular when starting from a complete stop. While a warped flywheel is sometimes the cause, clutch chatter can be difficult to diagnose as the pressure plate, the clutch disc, or the release bearing are often at fault whether the parts are worn, broken, warped, or contaminated by oil due to an engine or transmission leak.

3. Clutch slipping

Often, as you try to change gears while driving, the gears may slip. This typically happens when you can tell no power is being transferred to the wheels. This is often a direct result of a worn clutch. The slipping clutch will eventually cause the flywheel to wear out as well. You may start to hear grinding noises from the pressure plate and eventually, the flywheel and other parts in the clutch assembly will overheat and cause them to warp or even crack.

4. Clutch dragging

This is the opposite of a clutch slipping. Instead of the disengaging clutch, the clutch simply won’t completely release. You’ll experience various levels of gear grinding when you change gears or even the complete failure of putting the car into first gear when starting from a standstill.

Clutch drag isn’t a failure of the flywheel itself actually. It is the bearing or bushing in the flywheel or crankshaft assembly.

5. Clutch pedal vibrates

Along with this, there can be vibrations coming from the clutch pedal or floor of your vehicle each time you operate the clutch. These vibrations indicate that the flywheel’s spring mounts have gone bad. As you may know, the spring mechanism normally reduces the vibrations that are generated from the clutch being used.