From Ford to Ferrari and Porsche, almost every major automaker has poured millions of dollars into racing at one point or another. In addition to brand publicity, the other important reason they took on racing is to have a technological testing lab. With optimal performance in mind, automakers have continuously developed and perfected various car technologies that have migrated from the race track to mass-produced everyday vehicles.

It is not surprising that breakthroughs in race cars are almost always applicable in some form to mass-produced cars. Racing technology has influenced many of the components of the cars on the road these days, from the basic engine design, to the position of the ignition, and even the tires.

Read on to find out the most important racing car technologies that might be in your car and the interesting stories behind their innovations.

Contents

Top Car Technologies From the Racetrack to the Driveway

Aerodynamics

Here’s the basics: drag is the enemy of speed. Like airplanes and Japanese shinkansen or bullet trains, race cars typically come with sleek, sculpted designs to “slice” easily through the air with the least drag possible. Such aerodynamics is applied universally in today’s passenger cars with the purpose of boosting fuel economy and mileage.

Another race car technologies is the huge wings that create downforce to increase traction, keeping the vehicle on the ground. This is applied in high-performance passenger cars, like the Porsche 911 and Corvette Stingray, for better handling at high speed.

In addition, manufacturers now also employ underbody trays and sculpting like race cars to reduce turbulence and drag underneath the vehicle. This upgrade in passenger cars greatly reduces cabin noise.

Tires

Considering the high speed and quick turns on the race tracks, race cars’ tires have to withstand the most demanding conditions and heavy wear and tear. Manufacturers must blend traction, grip, and durability to create a winning formula. Many of these car technologies in tire performance have been adapted to the mass-produced tires, from those in a high-performance Chevrolet to those in a Jeep Wrangler.

Tire manufacturers design new tread patterns that can help cars maintain traction in the wettest conditions, grooves to grip uneven or loose surfaces, tread compounds that maintain grip at extreme temperatures, and tire core designs that can take more abuse in an hour than most tires will endure in a lifetime. You might be surprised to find that even a component such as tires take on many forms and materials, with the purpose of exceptional grip and durability.

Whether it’s a tire that can quickly resist hundreds of gallons of water per minute off of its surface, or a rally tire that resists rock punctures and a bumpy ride, all of these different performance-oriented tire types came from racing car technologies.

READ MORE

- How Long Do Tires Last And How To Make Them Last Longer

- Nitrogen Vs. Air In Tires – Which Is Better?

Disc brakes

Prior to the appearance of disc brakes on race cars in the 1950s, the drum brake design was the norm. Racing teams came to prefer disc brakes because they were powerful and easier to maintain than drum brakes. Disc brakes are also easier to keep cool despite the heat typically generated due to friction when brakes stop a car.

This heat actually reduces the stopping power of the brakes. Disc brakes can be vented, which allows the heat to dissipate. In present day cars, most have disc brakes on all four corners, with a few models having disc brakes on their front wheels.

Apart from the design, disc brake’s materials specially used in race cars are now showing up as options on some luxury sports cars. While most production cars have cast iron disc brakes, race cars use materials that are lighter and often more durable, including ceramic, which is much more expensive.

Many racing teams have also started using super light and super strong brakes made from carbon, which is very expensive, too expensive to show up on production cars for some time any time soon.

READ MORE

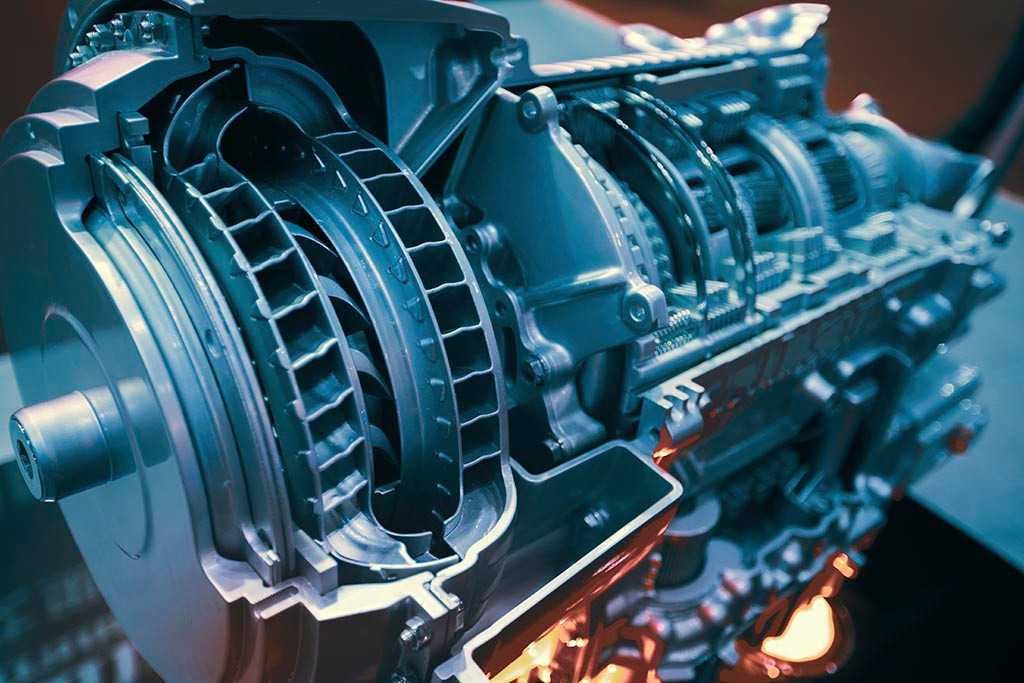

Transmissions

A while ago, when cars were changing gears, no power was sent to the wheels. To increase the speed of gear changes, racing engineers developed the dual-clutch transmission, providing lightning-fast shifting and no loss of power. In everyday vehicles, dual-clutch transmissions are operated like traditional automatic transmissions.

Another related innovation that came from racing is the paddle shifter. You can find them on a variety of models, from sports cars to luxury midsize SUVs.

The levers can be mounted on the steering column or steering wheel to provide quick access to gearshifts without taking your hands off the wheel. Paddle shifters can be used with dual-clutch transmissions, continuously variable transmissions, or automatics with manual modes.

READ MORE

Turbochargers and Superchargers

To help the engine generate more power, two things are needed: more air and more fuel sucked into the engine’s combustion chamber. It should be noted that a specific ratio is required for the engine to work: 14 parts air to one part fuel.

The air pumped into the combustion chamber is regular air at atmospheric pressure. The compressing happens later with the working of the piston, which moves up to compress the air and fuel mixture, thereby creating a “vacuum”.

The supercharger increases air intake simply by compressing air at above atmospheric pressure before pumping into the combustion chamber. With more air intake, more fuel can be pumped into the combustion chamber for the engine to combust to create more energy.

Turbochargers and superchargers have the same basic goal, that is to cram as much air into the engine as possible. The two technologies are similar but different. A turbocharger uses hot exhaust gases to spin a turbine that forces more air into the engine. A supercharger gulps more air by using a belt connected to the engine’s crankshaft to spin the turbine.

Since many turbocharged and supercharged cars have won races, many professionals and drivers as well as car enthusiasts have equated turbos with performance. This became effective marketing for such car technologies.

Turbochargers in today’s cars are as important for efficiency as they are for performance. Ford has built an entire lineup of efficient EcoBoost turbocharged engines that they use in cars from the subcompact Fiesta to the F-150 full-size pickup. Superchargers are found on several high-performance passenger cars, including the Dodge Charger Hellcat and the Audi A6 3.0T.

Multifunction Steering Wheels

The modern Formula One race car has a steering wheel covered with a myriad of buttons, dials, and displays. Race car’s wheel-mounted controls have arrived on passenger cars as well, although, or thankfully, are not as complex. They allow operations without having to locate a dash-mounted control.

The most common uses of wheel-mounted controls are for audio systems, cruise control, and information screens. Generally, they’re simple buttons that are driver-friendly.

Some more advanced applications are Honda’s innovative touch control for audio volume in the 2016 Civic and Mercedes-Benz’s touch and swipe functionality like a smartphone on the 2017 E-Class steering wheel.

Dual Overhead Camshafts

Another Engine101 basic that you should know: engines have valves that open and close to let air in and exhaust out. A camshaft in turn opens and closes the vales.

If you have two cams on your engine, called “dual cams”, the valves can be opened and shut more quickly, which allows for better engine performance. This type of car technologies first appeared on race cars in the early 1900s, and is still one of the most popular engine designs in production cars today.

Suspensions

The suspension is one of the racing car technologies that has translated almost directly to production cars. In car racing, it’s best to have all four tires maintain contact with the track for more stability. Traction also makes sure that all the power the engine creates is not wasted but is put into moving the car forward.

Like most production cars, race cars use independent suspensions. These suspensions allow each wheel to move without affecting the movement of the other wheels. Formula One cars use multi-link suspensions, which are available on a number of production cars.

Ayrton Senna’s 1987 Lotus Formula One car used a computer-controlled active suspension system that adjusted to changing track conditions. While such car technologies have now been banned from Formula One, it can be found on many models on the street these days.

So, why doesn’t your car handle like a race car? While the suspension types may be the same, the suspension adjustment of a Formula One car’s suspension is completely different from the adjustment on an everyday vehicle.

In a race car, the suspension has to keep the car stable through turns that generate more force than a production car could handle, as well as extreme acceleration and stopping. Since the two driving conditions differ greatly, do not go and adjust your suspension to mimic a race car’s capabilities.

Also, remember that your car has specialized suspension adjustments too. While it’s adjusted to balance comfort with performance in passenger cars, comfort is not a criteria for most race car suspensions.

An interesting application of race cars suspensions is General Motors’s Magnetic Ride Control. This is available on many of its vehicles, including the Chevy Corvette and Camaro, Cadillac CTS-V, and GMC Sierra Denali pickup.

Magnetic Ride Control uses a metallically infused liquid in the shock absorbers that changes viscosity when an electric current is applied. As a result, the stiffness of the shock can be changed in milliseconds.

Fuel Injection

Mercedes-Benz brought the first fuel-injected race car to Formula One in 1954 using a system developed by Bosch for applications in World War II. Before this, fuel was fed into the engine to create combustion by carburetors.

Before long, everyone else in the racing world was using the complex mechanical systems that provided more precise fuel delivery than carburetors.

READ MORE

- Carburetor Vs Fuel Injection: Which One Is The Better Option?

- What Are The Different Types Of Fuel Injections?

However, fuel injection didn’t become a common feature in the passenger car market until the 1980s, when emissions and fuel efficiency standards made carburetors obsolete. Many modern vehicles use an advanced form of fuel injection called gasoline direct injection to meet mileage and emissions targets.

Side note: For optimal engine performance, you should also pay attention to the fuel pump. A fuel pump, also referred to as a “fuel transfer pump”, is needed to transfer fuel from the fuel tank to the engine, specifically to the carburetors or fuel injectors, which disperse fuel into the combustion chambers of the engine.