As a variant of the internal combustion engine, the rotary engine is an old type in the lot. The engine is quite popular because it offers a smooth run and improved cooling. But where fuel economy has become the need of the hour, rotary engines fail to provide it.

The engine manufacturers already knew how rotary engines did not suit the future scenario, giving way to the introduction of static engines. The question here is why the fuel economy of the rotary engines is bad. Let’s unravel the truth with our maintenance tips as well!

Contents

Things You Should Know About Rotary Engines

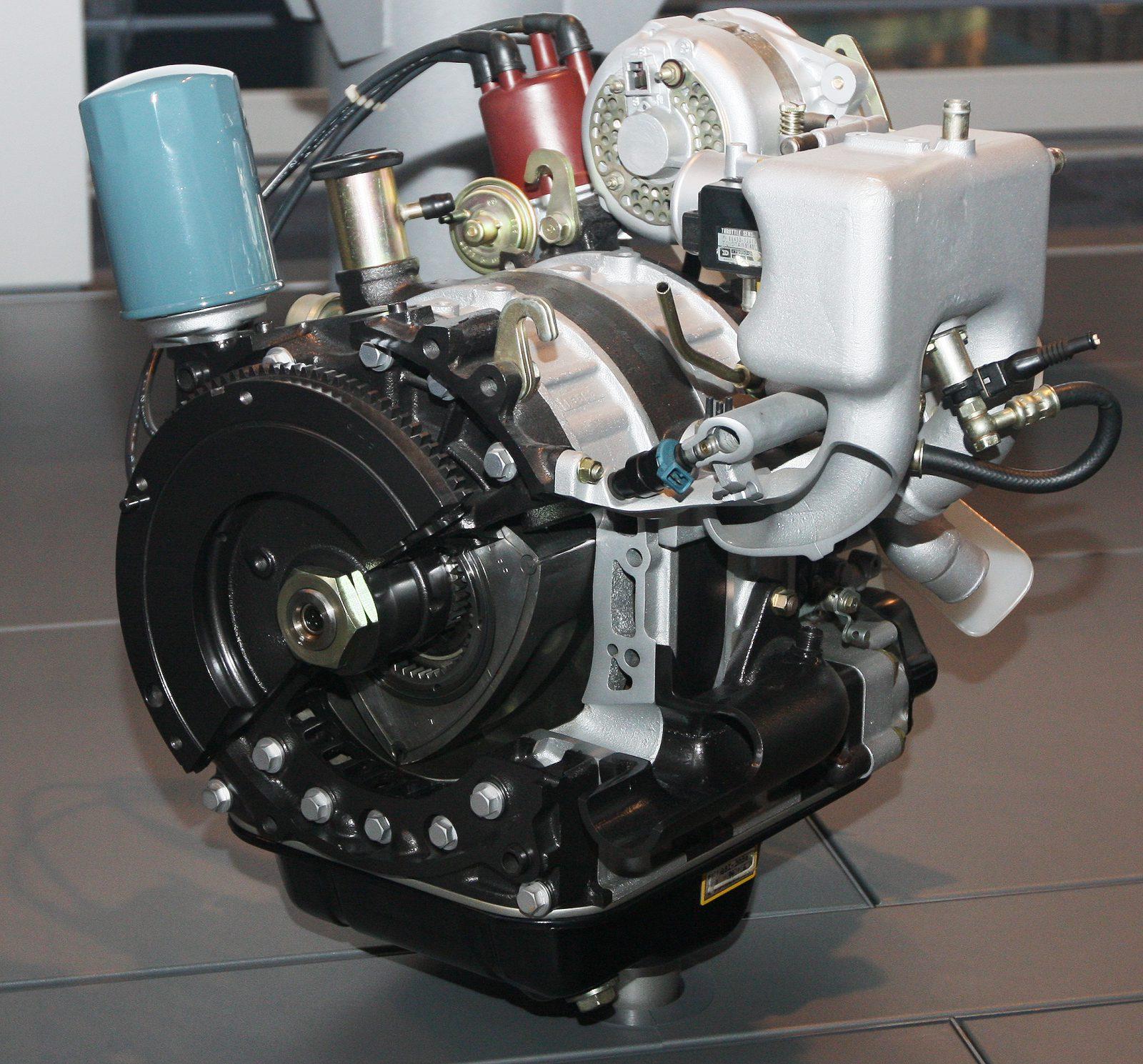

The rotary engine is also known as the Wankel engine. This is a type of internal combustion engine that was conceptualized and developed by Felix Wankel and he received the first patent for this engine in 1929. However, the commonly used Wankel engine is from Hans Dieter Paschke with significant improvements over the old version.

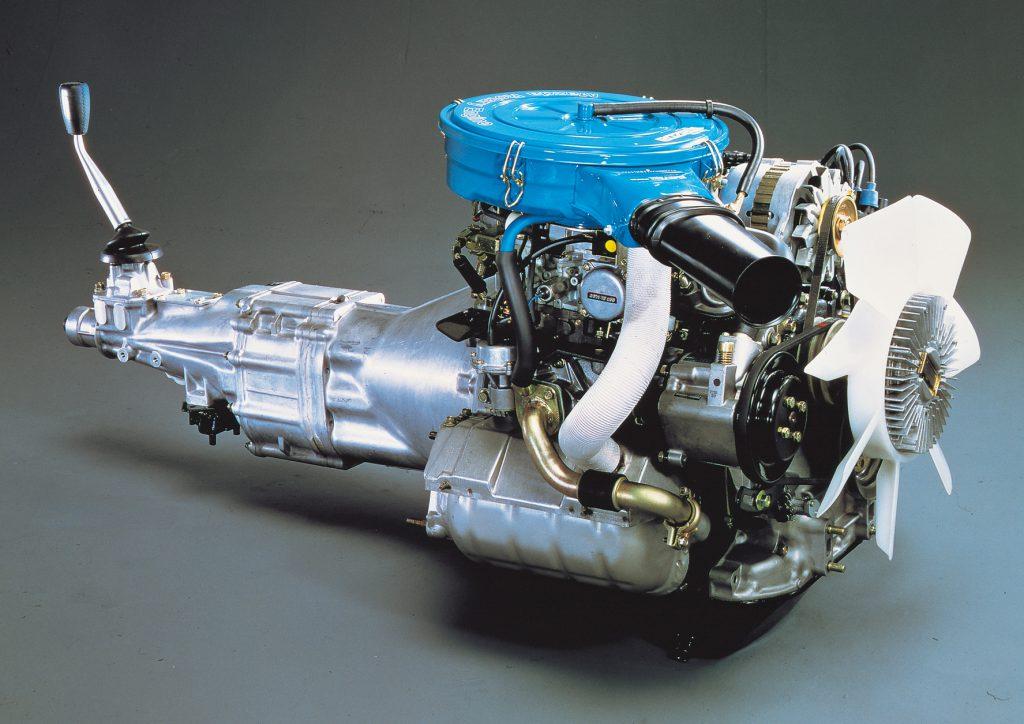

The Rotary engine was once installed on the legendary Mazda RX-8. This engine does not use a cylindrical piston that moves up and down, but it uses a triangular piston with circular motion. When this piston rotates, the intake stroke, suction stroke, and exhaust stroke will take place in turn at each position in the cylinder. Rotary engines are known for their advantages such as smooth operation with high capacity, economical production costs, and lighter weight than other engines.

Why Do Rotary Engines Offer Bad Mileage?

The rotary engine has a constant crankshaft, and the corresponding cylinder block revolves around it. The engine has its plus points and some drawbacks, but the low mileage offered by the rotary engine is a matter of concern.

1. The inefficient engines

The thing is; the rotary engines end up producing excessive power. The engines, in turn, are not built to handle the excessive power. The more power the more fuel is burnt as the revs of the vehicle get higher. These are the simplest reasons why rotary engines offer bad mileage.

See more:

- The Reason behind Rebuilding the Rotary Engine of Mazda RX8

- How Are Rotary Engines Good For Hydrogen Fuel?

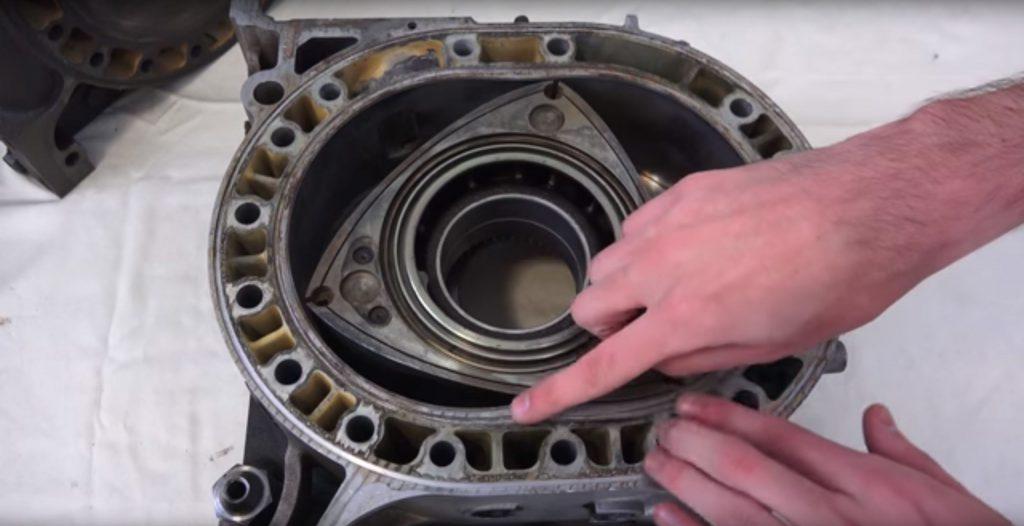

2. Seal leakages

The temperatures of each chamber of the engine house differ. This tends to be problematic when the diverse expansion coefficients of the materials lead to faulty sealing. Furthermore, a case of seal leakages occurs that results in leakages of combustion gas into the other chambers. Such wastage of gas directly means low fuel economy.

3. Low compression ratio

The compression ratio is the overall ratio of the maximum and the smallest volume of the cylinder at any given point within the internal combustion engine. The best compression ratio that has been recorded on a rotary engine is 11:1, which is not okay in terms of what modern engines can offer. The best compression ratio for a petrol engine is 10:1.

4. Long combustion chamber

The combustion chamber of a rotary engine is designed to be very long. This may work well to some extent, but the high surface area to volume ratio makes things tricky. You may ask, ”How may it affect fuel consumption,” to which the answer lies in the extended cooling time of the fluids. If the cooling is suffered, so is the overall fuel economy.

5. The case of fixed ports

The valves or camshafts are missing in a rotary engine. This problem with the rotary engines leads to the inability of meddling with the valve timings, i.e., the case of “no valve timing.” The port time can only be changed by machining the ports or altering the piston skirt. So, when the valves do not open and close at a synchronized timing, the engine performance deteriorates. In simple words, the rotary engine fuel economy turns out to be bad.

Why Is The Rotary Engine Not Commonly Used In Vehicles?

Despite having several advantages, the rotary engine is still not chosen by many automakers to equip modern “machines” because:

- The engine produces low-temperature efficiency: The combustion in the rotary engine is designed in a long oval shape, so the thermal efficiency is relatively clearly reduced. This also causes unburned fuel to be ejected from the exhaust pipe, thereby causing more fuel consumption.

- The time for a complete combustion cycle is quite long: Because the combustion is designed to be long and move continuously, it takes quite a long time for the rotor to complete a cycle. Furthermore, too large a temperature difference between parts of the rotor leads to different thermal expansion phenomena, affecting the rotor’s performance. Accordingly, the life of a rotary motor is often lower than that of a conventional reciprocating piston motor.

- Pollutes the environment: In fact, this engine cannot pass an emissions test in Europe. Engine oil leaks during operation (due to the too-simple structure of the rotary engine) as well as fuel escaping from the exhaust pipe before being completely burned, causing the car to have quite a high emissions rate.

Wrapping Up

These are the few reasons why rotary engines do not offer good fuel economy. Having understood that, you know why better counterparts are replacing the engine. You should know that the engine is on the verge of extinction as it destroys the efforts to maintain an impressive carbon footprint.

you’re speaking nonsense. rotaries dont have valves like piston engines do, and a camshaft to drive those valves.

See section 5, sentence 1: “The valves or camshafts are missing in a rotary engine.”