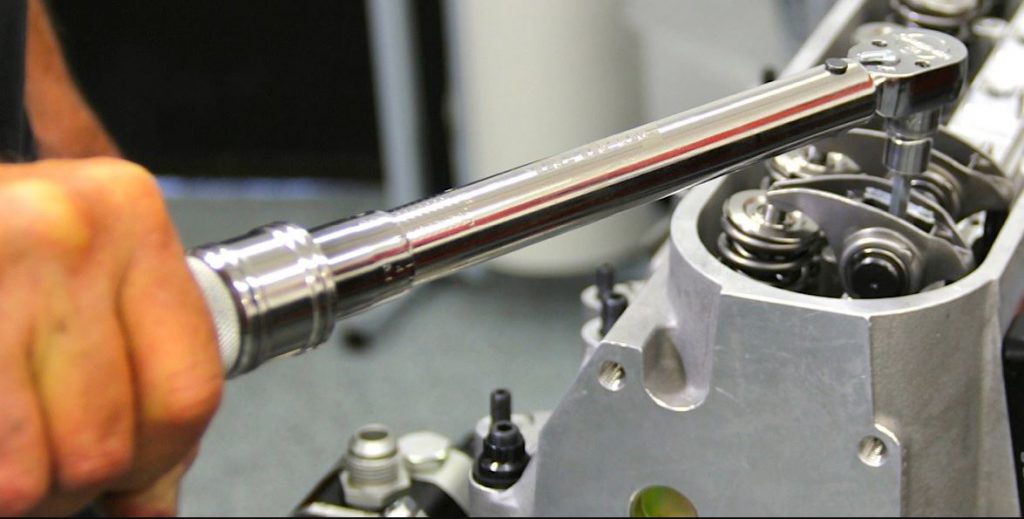

An important tool for every mechanics and car owners to execute force, which is a torque wrench. To tighten bolts and nuts, you will need torque wrenches to apply proper force. In order not to overtighten or strip them, there are some specifics that you need to consider when buying a torque wrench. If a fastener is too loose or too tight, it could fail during working because of the continuous vibration or force strain. To avoid these problems, buying a good quality torque wrench with these 5 key factors is crucial for your tool set.

Contents

Why Do I Consider Buying A Torque Wrench?

If you need to fasten torque efficiently and accurately without using hard physical work, you will probably think of buying a torque wrench. When you are driving, there will be vibrations that can loosen bolts and nuts. A fastener with properly torqued force will remain tight without the effect of those vibrations. In addition, if the bolts or nuts are too loose or too tight, the whole operation could be failed. Therefore, you should consider the following 5 things to buy a good torque wrench.

5 things to consider when buying a torque wrench

-

Quality

The first aspect to be consider when buying a torque wrench must be its quality. The work done with the torque wrench is related directly to the construction of the machine. Therefore, a torque wrench with low standard can ruin the fluency of the system. Instead, a high-quality wrench can prevent the inefficiencies of the process to the minimum and help you lower the cost for further repair.

The make materials used can determine the quality of a torque wrench. You can find out there many choices of cheap wrenches made from plastic materials. Clearly, everyone will conclude immediately that these wrenches will not last long even though it would work well in their short lifespan. Also, cheap and low-quality wrenches will affect the accuracy while you are working. It is recommended to choose a metallic made one. They can last for longer time and stable for years.

-

Accuracy

This is one of the most important things to consider when buying a torque wrench. Torque wrenches have different accuracies. Always try to find a wrench with an accuracy of plus or minus 5%. It would be even better if you can get a smaller amount of that. Because precision is always important in most of the tasks that a torque wrench will be used for, it is highly recommended that you should look for the accuracy of each one you pick.

-

Type

There are some several types of torque wrenches that you should know. When buying a torque wrench, you should know the purpose of it to select the right one.

-

Beam Torque Wrench

This is the oldest type as we handed it down from generation to generation. It works by applying circular force to the handle clockwise or vice versa. If you need to tighten the bolt, just turn the wrench’s handle clockwise. If you want to loosen or detach the bolt, turn the wrench’s handle in counterclockwise. Really easy! However, there are still some disadvantages. One is that it is unable to provide any type of physical or audible feedback indication after reaching the desired level of torque. And the other is that most models can only be used in one direction for tightening nuts or bolts. A beam type of wrench cannot provide a versatile direction choice.

-

Micrometer Torque Wrench

If you are considering buying the most used and most versatile torque wrench, you will probably look out for the Micrometer Torque Wrench. To set up the torque, all you need is to twist the handle until it reaches the correct torque setting on the barrel of the tool. Rotating the handle clockwise tightens a spring inside. When you apply torque to a nut or bolt, the tool will click when the correct torque has been reached. The biggest advantage of the Micrometer wrench is its flexibility for either left or right-hand operations. One of the disadvantages is that because of the force being applied to wearing parts such as an internal coil spring, they require regular recalibration.

-

Electronic Or Digital Torque Wrench

Electronic or Digital torque wrenches have a digital readout screen which let you set the torque limit as your desire. Of course, it will be more costly than the beam one. But electronic or digital wrenches have come down in price in the last few years. Now you can afford one in most automotive stores.

SEE MORE:

- What Is Torque In Car? Things That You Must Know!

- How To Calibrate A Torque Wrench

- How To Use A Torque Wrench And Other Facts

-

Interchangeable Head Torque Wrench

This is one of the new products that is put out on the market. An interchangeable head torque wrench is generally supplied in a kit with a standard ratchet head and a variety of open-end heads in different size. This one is a very economical tool that gives you so much for your money. This tool is suitable for many applications including accessing nuts and bolts in tight areas.

Those are some types of torque wrench that you can consider when buying one. There are some other types of it in the market for you to choose. But just to remind, you have to identify the usage of it. Then, you can purchase the one that suits your work the most to save your money and your time.

-

Capacity

In order to satisfy nearly any requirement, suppliers are producing various models of high capacity torque wrenches. If you can determine the purpose of the tool, acquiring a high capacity torque can become very easy. Otherwise, it will lead you to a dishonest and incorrect buy.

These tools have different uses for both the industrial and the automotive sector. Based on their capability and scale, they are classified as small, medium, and large types.

- Small sized torque wrenches provide torque range varying from 30 to 200 inches supplied with 3/8” or 1/4” square drive.

- Medium torque wrenches with low range varies from 20-30 ft lbs. and high range of roughly 250 ft lbs. Usually, 1/2” square drive is supplied with these types of torque wrenches.

- High capacity torque wrenches are suitable for heavy industrial and automotive use like machinery, large plant and truck maintenance. These can probably provide up to 1000 ft lbs. of torque range.

-

Grip

During your work, fluid and grease may cover your hands while using a toque wrench. Therefore, you must keep an eye on the grip. When picking a torque wrench to purchase, a nice grip matters a lot. Imagine using the wrench when it is too slippery, you will have trouble in getting your work done. So, when buying a torque wrench, take a look at the grip and find a material that prevent the most of slipperiness.

Conclusion

A torque wrench is a precision instrument, and it is worth investing in a quality product. In the market, there are many types of torque wrenches for consumers to choose but not all of them can satisfy your requirements. Use all of the tips we have discussed to choose the perfect one for yourself. A nice one is both economical and efficient to save your money and your time of getting your work done.