Are you curious about what happens when you turn the steering wheel of your car? Normally, there are many types of mechanisms for steering, like a recirculating ball or electric power one, for example. Rack and pinion also is a steering system that you may have heard before

A rack and pinion steering system is made up of a pinion (circular gear) and a rack (linear gear). The system converts revolving motion into linear motion. Most cars, small trucks, and SUVs have a rack and pinion steering system, as opposed to the recirculating ball steering found in larger trucks, SUVs, and other heavy-duty vehicles.

Contents

History of Rack and Pinion

Although rack and pinion steering is relatively new in the history of automobiles in the United States, it is not a new concept. The first rack and pinion gearboxes were developed by BMW in the 1930s, but they were not sold in the United States until the 1951 MG, and they were not used in the production of American models until the 1974 Ford Mustang II and Pinto. AMC used rack and pinion in Pacers from 1975 onwards, but GM and Chrysler did not use them until the early 1980s X-bodies and K-Cars.

Manufacturers in the United States saw rack and pinion as logical. It had been used for many years by European and Asian car builders, and it was a simpler design than the recirculating-ball steering gearboxes, so it was less expensive to manufacture. Rack and pinion steering is also much lighter than a traditional gearbox, which means better gas mileage. Idler arms, center links, tie rod sleeves, and pitman arms are not required with the rack and pinion design. This, in addition to the weight loss benefits. Rack and pinions are much easier to integrate into a front-wheel-drive system because they can be mounted close to the transverse drivetrain. Gearbox ratios could also be tailored to each wheelbase as well as handling and option packages. Rack and pinion gearboxes also provide the driver with a firmer feel in the steering wheel, which translates into better overall handling.

Rack and pinion systems are used not only for steering cars and small trucks but also for a variety of other purposes. Rack and pinion systems are not only used to assist trains in climbing steep gradients, but they also provide better brake control, especially in snowy and icy conditions. They are standard features in the majority of stairlifts. The rack and pinion mechanism is frequently powered by hydraulic or electrical energy.

Arthur Ernest Bishop invented the variable rack in the 1970s. His variable rack was used to improve vehicle handling when combined with a standard pinion.

Ratios of Rack and Pinion

To go from lock to lock, most cars require three to four full turns of the steering wheel (from far right to far left). The steering ratio indicates how far you must turn the steering wheel in order for the wheels to turn a certain amount. A higher ratio indicates that you must turn the steering wheel more to turn the wheels a certain amount, whereas a lower ratio indicates that the steering responds more quickly.

Variable ratio steering is used in some vehicles. The center of this rack and pinion steering system has a different number of teeth per cm (tooth pitch) than the ends. As a result, when the steering wheel is turned toward the lock, it is more sensitive than when it is close to its center position, making the car more maneuverable.

There are two main types of rack and pinion steering systems:

- End take-off – the tie rods are attached to the end of the steering rack via the inner axial rods.

- Centre take-off – bolts attach the tie rods to the center of the steering rack.

SEE MORE:

- Steering Rack And Pinion Leak: Warning Signs And Causes

- Car Pulls To The Right: The Possible Reasons And Solutions

How This System Works

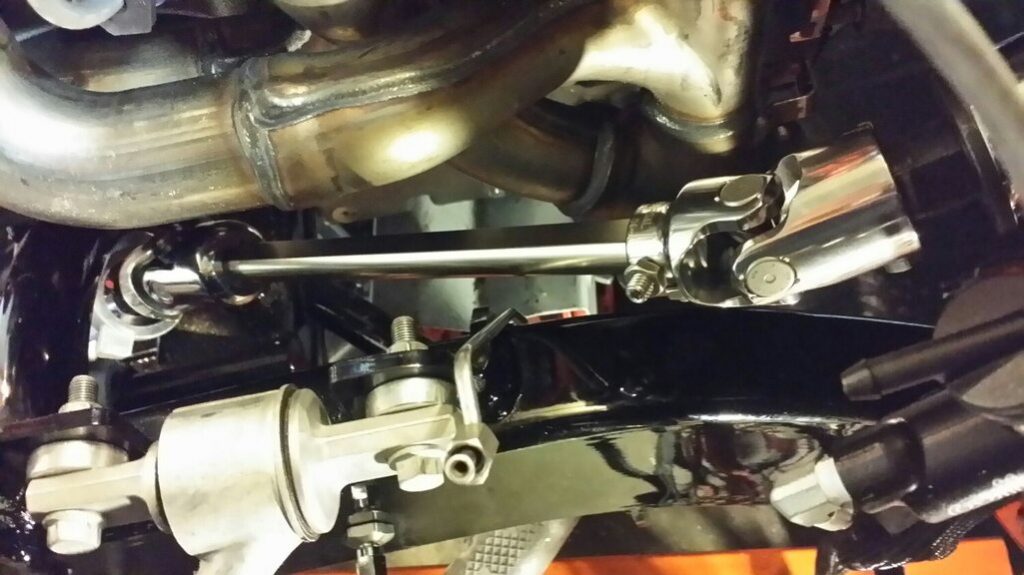

Rack and pinion steering works by converting the circular motion of the steering wheel into the linear motion required to turn the wheels via a gear system. The gearset is housed in a metal tube. The tube has openings at both ends that allow the rack to be attached to an axial rod. The pinion gear is connected to the steering shaft so that when the steering wheel is turned, the gear spins and moves the rack. The axial rods are linked to a tie rod end, which is attached to the spindle.

The rack and pinion gear set serves two purposes:

- Conversion of the rotational motion of the steering wheel into the linear motion required for the vehicle’s wheels to turn

- Reduction of gears, which makes it easier for the steering wheel to turn the wheels

Signs of Problems

Since rack and pinion are basically gear mechanisms, they will wear out and fail over time. Just like almost any other component in your car really. Here are the signs that Maintenance Tips think you should pay attention to:

Excessive Play or Loose Steering

Your steering wheel should feel “tight” when you operate it. That is, when you turn the steering wheel, you can feel the front wheels turning. If your rack and pinion are failing, you will notice the steering wheel will start to feel loose or there’s an excessive play on the steering wheel. It will often feel like your car is slow to respond when you turn the wheel. The car will also feel more difficult to control and can wander at high speeds.

At some point, you may also feel a numb spot. This is when you turn the steering wheel, but the front wheels aren’t turning until you turn it to a certain angle. This happens because the rack and pinion aren’t gripping each other, which means the rack isn’t actually moving when you turn the wheel.

Noise When Turning

Your car may also make a clunking noise when you turn the steering wheel. A worn-out rack and pinion may not have enough lubrication and are hitting and grinding against each other, making a noise in the process.

Keep in mind that these noises may come from the tie rods or other suspension components. The difference is that if the noise stems from a bad rack and pinion, you will hear the noise almost every time you turn the wheel. Meanwhile, clunking noises that come from the suspension assembly usually only happen when you go over bumps or make a tight turn.

Leaking Power Steering Fluid

If you have hydraulic power steering in your car, you may start seeing a power steering fluid leak when the rack and pinion are failing. If you see a puddle of red fluid under your car, this can either be a power steering leak or a transmission fluid leak. Check where the leak is coming from to verify whether it’s the power steering fluid or the transmission fluid.

Keep in mind that a power steering leak can happen because of a bad power steering pump, faulty reservoir, or leaky lines. Your rack and pinion may not be the cause in the first place. Additionally, if your car has electric power steering, then you won’t see this problem. This is because electric power steering doesn’t require any fluids to operate.

Replacement Costs

A rack and pinion replacement will cost anywhere between $1,000 – $1,900 including labor, depending on your vehicle’s make and model. The rack and pinion themselves are usually around $700 – $1,500, while labor costs will set you back as high as $400. For example, the rack and pinion for a 2015 Toyota Corolla will cost you $717, add a labor cost of $400 and you’re looking at a repair bill of $1,117.

Of course, these are just rough estimates, and we’re taking the higher end of the spectrum. The rack and pinion replacement for your car may be cheaper than our estimate. Needless to say, luxury and high-performance cars are likely to cost more. The good news is that rack and pinion usually last quite long. They will usually last for about 100,000 miles and they can easily last more than that. My Mitsubishi Pajero Sport for example has done 120,000 miles and is not showing any steering problems.

With a replacement job this expensive, you’re probably wondering, is it actually worth it? Before you give your mechanic the go-ahead, it would be wise to check your car’s resale value in the secondhand market. If your car’s value is still well above the repair job, then we would say the cost is worth it.

For example, if the rack and pinion replacement will cost you $1,200, but your car can still be sold at around $10,000, then the repair job is definitely worth it. However, if your car’s resale value is only around $3,000, then it’s not worth it. That’s almost half of your car’s value! In this case, you’re probably better off just selling your car as-is.

Another option would be to scrap your car. You can either take it to a scrapyard or a scrapping company that will pay for your car’s metal value. Or you can also take your car apart and sell individual parts and accessories. The latter is a time-consuming option, but you’re likely to get more money out of your car. Bottom line, don’t proceed with the repairs if your car’s market value isn’t far off from the repair cost.

Conclusion

So, to summarize, the rack and pinion are the heart of your car’s steering system. The rack is a linear gear that connects to the tierods which are ultimately connected to the front wheels. While the pinion is a round gear that sits on top of the rack and connects to the steering wheel via a steering column.

The rack and pinion will last up until about 100,000 miles. But they can wear out, and when they start to fail, you will see some noticeable symptoms. Some symptoms include clunking noises when you turn the steering wheel, leaking power steering fluid, and a loose steering wheel with a lot of play. This obviously makes steering and car control more difficult. This is why you shouldn’t drive a car with a bad rack and pinion as this can lead to a major accident.