Located in the lower engine block, cylinder head, or intake manifold, the Knock Sensors are made to create the voltage signal based on the vibrations that are caused by the detonation.

The sensors basically cause the voltage signal based on the vibrations that detonation causes. The computer then simply uses this signal to hold back the timings, whenever the spark knock takes place.

For those, who are still wondering about how does a knock sensor work; here is a complete walk-through to understand how it actually works.

Contents

What Is A Knock Sensor?

Definition

A knock sensor is like the car’s ears for the computer. It listens for any unusual vibrations that could harm the engine and checks if the engine is running smoothly. Imagine it as a microphone, picking up on something called “spark knock.”

This is when the fuel starts burning too early in the engine. Spark knock goes by other names like detonation, pre-ignition, or pinging.

Hope this definition helps you with some ideas on what is a knock sensor and what does a knock sensor do.

SEE MORE:

- Crankshaft Position Sensor – Every Function Explained

- Here’s how you test a coolant temperature sensor!

Function

So, we know that this “sensor”, which is a microphone, listens to the “knock”, but how does it sound? The answer is like a can full of marble is being shaken and produces a rattling sound.

This unusual pulsation creates a rattling sound and causes harm to the internals of the engine. So it needs to be detected by the computer when it happens.

That’s why the knock sensor functions came into existence, to be supportive of the computer for this detecting task.

When the irregular knock happens and is detected by the sensor, the computer will know it and immediately make small adjustments to keep it from happening with optimum performance as usual.

And if the sensor fails, the computer will just make no adjustment to the engine and thus optimum performance of the engine is not guaranteed then.

Uses

Well, knock sensor comes with two main uses:

- First, it detects the spark knock, which allows the optimum performance of the engine.

- Second, it secures the engine from power-robbing as well.

So, a knock sensor keeps the vehicle safe, allowing you to drive safely on the roads.

How Does A Knock Sensor Work?

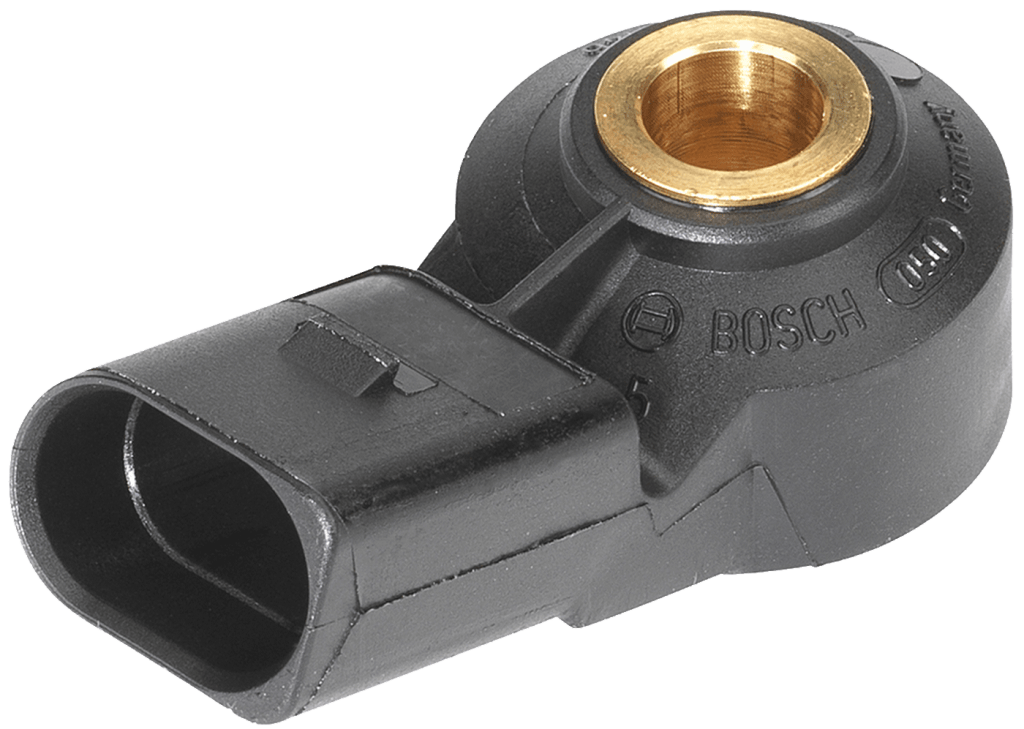

This part will educate you with technical details of the working, or how does a knock sensor work. In technical words, the knock sensor is a piezoelectric sensor which contains a piezoelectric sensing crystal and a resistor.

This crystal creates a small amount of voltage when shaken by the mentioned rattling sound. The knock sensor takes advantage of this unique property then.

Knock Sensor starts the work as soon as it senses the knocks and the noises of the engine.

So, the sensor simply picks the noise, which is usually not audible in the engine. The low volume reverberations range from 6 to 8 kHz.

The resonating plates inside the knock sensor are responsible for these low reverberations. Further, this is then transmitted to the piezoelectric crystalline element of the sensor.

As soon as the element receives this signal or as they call it the shock wave, a small voltage is generated, which simply goes to the electronic control unit of any vehicle.

The electronic control unit of your call will simply delay the firing of that spark in the chamber. As a result, the spark or the detonating of the spark knock is simply delayed.

In short, if you know some maintenance tips to keep your knock sensor healthy, there is no way any sort of spark will happen in the vehicle.

Now, as we have known how does a knock sensor work, let’s explore some of the symptoms for failure.

The Knock Sensor Troubleshooting: The Symptoms

After getting to know how does a knock sensor work, it’s about time for us to know why it is not working.

There are some common to rare symptoms of bad knock sensor that any driver needs to know to ensure the ride to be smooth and effective.

Driving Sense

First thing, trust your gut, trust your inner self when you are driving at speed or carrying a light or heavy load in the car.

There will be something that has gone wrong. Your car is not operating as it should be or at least you feel that it should be.

By listening to the engine sound, by watching the speed change, by comparing the weight of your gas foot with the last time or just steering speed.

When it comes to feeling, only your skills, experience and familiarity with your cars can tell. Then after confirmation, take your car to the garage right away for a quick check.

Slow Acceleration

Losing fuel mileage is what you will notice, especially at times of acceleration on highways. Deeper gas pedal doesn’t mean a quick speedometer anymore.

In other ways, with the same distance you are used to traveling, the fuel mileage goes down from F to E faster than it is supposed to.

And to you this is the pain in the pocket, and you can see that more money on fuel this week but no change to overall travel distance. You feel this clearly, and painfully.

Then wait no more, to the garage service we go, before you suffer more from engine damage.

Check Engine Light

A malfunction indicator lamp (MIL), or check engine light, is a tell-tale that a computerized engine-management system uses to indicate a malfunction.

Found on the instrument panel of most automobiles, it usually bears the legend check engine, service engine soon, or a pictogram of an engine – and when illuminated it is typically either an amber or red color.

In this case, the computer can detect different sounds in the engine. And when there is no usual signal from the Knock Sensor, the computer will get the information and will assume there may be a problem with the knock sensor. Then the Check Engine Light will turn on.

Of course there would be dozens of reasons for the Check Engine Light to turn on but it’s always worth taking your car to the mechanic. Whether it’s your knock sensor’s failure or not, you will save your money.

Power Loss

When the knock sensor is not working properly and the computer realizes that, the vehicle will lose engine power. The most damaged engine should normally be the high-compression and flex-fuel ones.

The result would be slowing the timing and keeping transmission out of drive. Replacement of the knock sensor will fix this.

Our Expert Advice

In any vehicle, a knock sensor can detect the noise at different levels. And, of course the spark plug color can also be identified in the vehicle.

So, when a mild knock occurs, you will probably hear the pinging sound, which will be just like the small ball bouncing around the engine of the vehicle. Well, this level of spark knock is easily identified by the knock sensor.

In case you are not taking good care of your engine and vehicle, chances are that these sounds may go to higher levels, resulting in more severe knocks and sounds in the engine.

This may even sound like someone banging the door really hard. After this, you can only expect your engine to get damaged and fail.

So, always check the knock sensor of the vehicle at least once in a month for its smooth working.

And please don’t try to fix the knock sensor itself. The good news is that it won’t cost you an arm and a leg to replace a faulty knock sensor.

If you have a standard vehicle, you can expect to pay somewhere from $120 to $500 for replacing your knock sensor. The parts cost will be from $65 to $200, while the labor costs will be from $50 to $350.

Therefore, learning to replace the knock sensor at home and buy the part from the shop is strongly recommended for any mechanic apprentice. Of course it will save a ton!

where is the position of the knock sensor ???