A secondary air injection pump is a part of the automobile exhaust system. It reduces harmful exhaust emissions at the time of a cold start phase. How does this pump actually work and how can you troubleshoot if it shows warning signs of going bad?

We’re going to discuss the basic functions of this pump and how to find the issues to control the rate of exhaust emissions.

Contents

What does a Secondary Air Injection Pump do?

No automobile engine in the world can operate at its full efficiency. There will always be some fuel that the engine cannot convert into mechanical power during the combustion process. This burning process takes place in the primary air injection system or the induction chamber.

So, the unburned fuel or hydrocarbons are the substances that the primary air injection system cannot handle. What happens to these hydrocarbons?

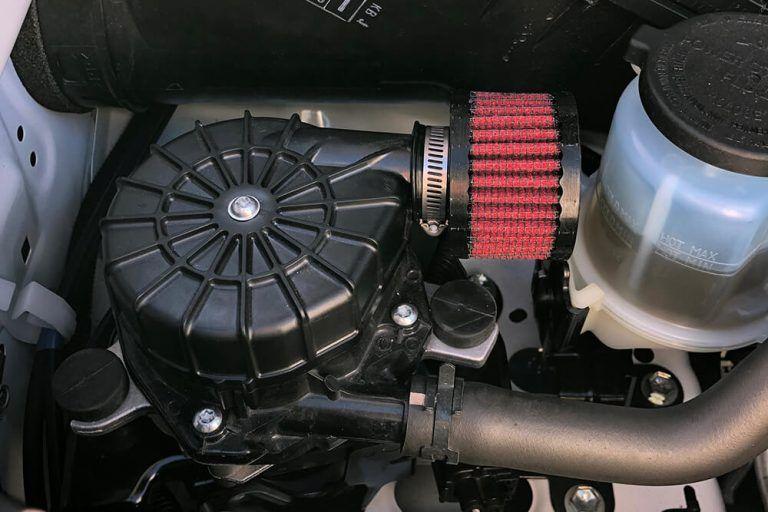

A secondary air injection pump works as a cleaner; cleans up the hydrocarbon leftovers. Without this pump, more toxic gases would have been released into the environment. Unburned fuel is more toxic than the gases produced from burned fuel. So, it should not be released outside, for reducing air pollution and avoiding an emission test failure.

Unburned fuel out of the engine is surrounded by various gases, but it needs pressurized air to burn this fuel. The air pump supplies that pressurized air into the exhaust system right after the exhaust manifold. This burns the hydrocarbon, thereby cutting their journey before they can get out through the exhaust pipe.

This air pump plays a vital role in helping the car to achieve the standards of government emission tests.

Diagnosing a Secondary Air Injection Pump

When a secondary air system does not work properly, emission increases during cold start and warm-up time. The Engine Control Unit (ECU) monitors this secondary air system. It triggers the engine indicator light when the pump does not work efficiently.

Why does it happen, though? What does affect the regular functioning of the pump?

It seems the presence of moisture in the system prevents the pump from hosing down the pressurized air. Another reason the pump can stop working is defective ground and voltage supply. The entire secondary air ignition system can fail due to a malfunctioning combination valve, and the most common reason for this problem to occur is a leaked or blocked line in the system.

SEE MORE

How to Diagnose the System?

The first rule of diagnosis is to do a visual inspection. Check each component for any visible signs of damage. For example, there could be a leak in the cables or the hose fittings could be loose. All the joining points and the connecting points of the hoses should not have any grazing marks or any other damaging signs.

The lines must be clear for the pressurized air to travel freely. There should also not be any blown fuses. However, if you find nothing during this visual diagnosis, move onto the next steps:

Perform an acoustic check.

The sound of a working electric pump will be quite audible when the engine is cold and at idle. When you switch off the engine, you will clearly hear how the pump stops.

If the secondary air injection pump sounds normal in the acoustic test, go on and perform a few more checks.

Reading the stored faults.

Check the fault memory to see if there are any stored faults. You can easily rectify them if there is any.

Otherwise, apply the actuator test to switch on the electric pump. This test is also useful in checking whether or not the combination valve is working. To do that, you will need to detach the vacuum line that connects to the combination valve. Then, kick off the cold engine to see if the system is working. You can also examine the control relay during the same testing.

Check the vacuum and control valve.

There is a vacuum at the control valve fitting and you have to check whether it’s working properly when the secondary air pump is in action. A vacuum pump could be there that requires checking too.

If there is no vacuum, the control valve triggering needs a check-up. Use a multimeter for the testing. If everything is working fine, move to check the combination valve.

Inspect the combination valve.

You have to use a vacuum pump to inspect whether the combination valve is running properly or not. To do this, you have to detach the valve’s vacuum line and connect the pump to the valve.

A hose fitting connects the combination valve to the secondary air ignition pump. Loosen the fitting and blow air inside with a little pressure, which must close the valve. Now, apply a vacuum and blow air again, and the valve should be open. If that does not happen in that sequence, there is a problem with the combination valve.