Knock! Knock! Hear a strange knocking sound coming from inside the engine and are struggling to find the rod bearings replacement cost? Then you’ve found the right place! This article will answer all your questions about this issue!

Contents

What Are Rod Bearings In An Engine

Rod bearings are also called connecting rod bushings, which are split bushings, consisting of two identical semicircular halves. When installed in the engine, they form a circle.

The rod bearing is carefully installed into a separate cavity. Usually both the cavity cover and the engine body have recesses so the bearing can slide inside.

So what is the purpose of this component? And why installing the crankshaft without rod bearings isn’t advisable?

Each piston within your engine is connected to rod bearings, and these components serve critical roles in maintaining engine balance and lubrication. The primary reason you can’t simply install the crankshaft without them is twofold.

Firstly, rod bearings ensure that the piston maintains the correct balance with the crankshaft, ensuring even and stable operation. Their role is to eliminate any play or excessive movement, as any imbalance inside the engine can lead to performance issues.

Secondly, these rod bearings play a vital role in keeping your engine’s crankshaft well-lubricated. Each bearing is designed with enough clearance to allow a controlled flow of oil.

This controlled flow creates a protective layer between the rod bearing and the crankshaft, preventing excessive wear and promoting long-term engine health.

If there is a lack of oil or the oil is contaminated, it can significantly impact the lifespan of the bearings. In such cases, the bearings may wear out prematurely, necessitating replacement. This raises the question of rod bearing replacement costs, which we will cover shortly.

What Is The Rod Bearings Replacement Cost

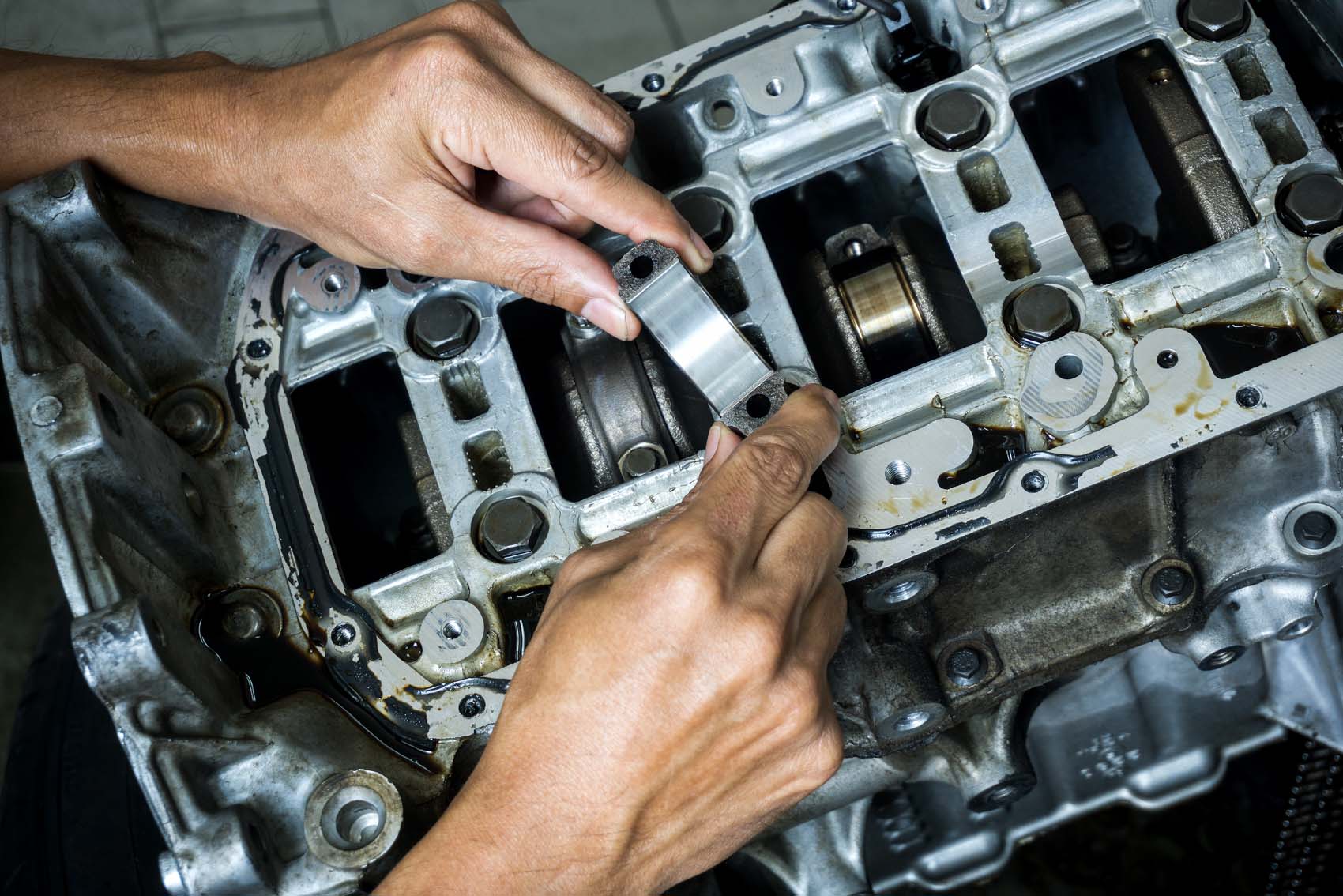

Rod bearings replacement

Understanding the average rod bearings replacement cost can be overwhelming, but this detailed breakdown will help you navigate the process like a pro!

Rod Bearings

Engine type and brand: The cost varies based on factors like car model and performance.

Standard vs. performance: Performance bearings offer higher load capacity but cost more.

Price range: $50 to $400+ for a full set of bearings.

Gaskets and Seals

Replacement needs: Some gaskets and seals may be reused, while others need replacing based on condition. Cost range: $20 and $100 depending on the specific parts needed.

Engine Oil and Filter

Essential for clean lubrication: Always use high-quality oil and filter recommended by your car’s manufacturer. Cost range: Around $30 to $50 for both.

Miscellaneous Parts

Fasteners, clips, etc.: Depending on your car’s condition, some minor replacements might be needed. Cost: $10 to $20 on average

Shop Supplies and Fees

Some shops add fees for supplies like cleaning materials and waste disposal. Expect around $10 to $20

Taxes and Fees (Location-specific add-ons)

Vary by region: Depending on your location, applicable taxes and fees might add a small percentage to the total cost.

In short, you should always get quotes from multiple mechanics and be upfront about your budget constraints. Remember, a higher price doesn’t always guarantee better service, so research your options carefully!

Cost of labor

Labor costs of rod bearings replacement typically represent the most substantial portion of the expense when replacing rod bearings.

You’ll need to consider your mechanic’s hourly rate, which falls in the range of $95-$100. However, hourly rates can vary, ranging from $15 to $210 depending on your location.

Moreover, if you leave your vehicle at the center, you may incur daily lot fees, typically $5-$25 per day. Given that this repair can require up to 20 hours of work, these fees can accumulate quite fast.

Lastly, there’s often a shop fee, which can amount to 5-20% of the total bill. If you’re paying $3,000 in labor costs, an additional 20% repairing center fee can be a substantial addition.

Other parts included

If your rod bearings are showing signs of wear, simply replacing the bearings alone may not suffice. It’s often necessary to replace additional components like cylinder head bolts and gaskets.

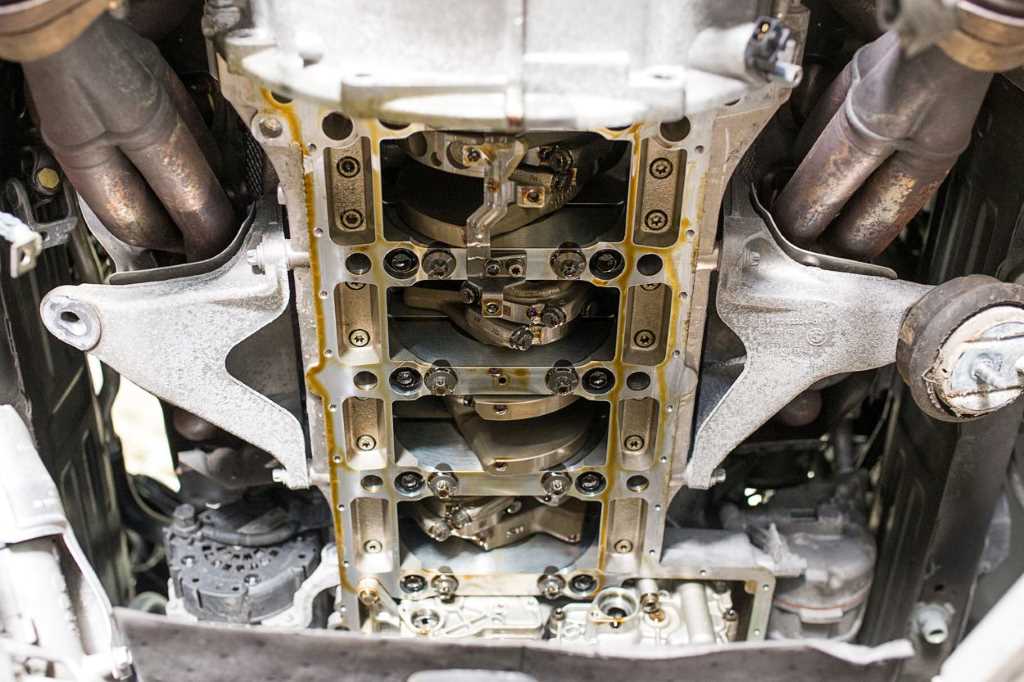

Moreover, if the damaged bearings have caused harm to the pistons or crankshaft, more extensive repairs may be needed, potentially requiring the replacement of both components.

For instance, in cases where a bearing has spun, it can become fused to the crankshaft, making repair impossible. This situation would necessitate the replacement of the crankshaft, along with resurfacing the engine block and possibly installing new pistons.

What Causes Rod Bearing To Fail

Aside from the rod bearings replacement cost, you should take a closer look at some main causes of this component’s failures.

As you may be aware, rod bearings can wear out over time, leading to significant engine problems. So, what exactly causes this wear and tear? Let’s explore these factors in the upcoming sections.

Subpar Bearing Quality

The initial cause of rod bearing failure, and consequently the need to understand the cost of rod bearing replacement, often stems from the use of low-quality bearings.

Certain engines are particularly vulnerable to premature rod bearing failure. While not all engines are affected, there are some that experience bearing wear sooner than expected. Notably, high-performance BMW engines, such as the S62, S54, S65, and S85, are known to encounter rod bearing issues.

Therefore, when considering the purchase of an M5 or M3 with one of these engines, it’s crucial to check whether the rod bearings have been replaced previously.

If they haven’t, a thorough engine inspection is essential to determine if any damage has occurred to the crankshaft. Now, let’s move on to other contributing factors before discussing the rod bearing replacement cost.

Low Oil Level

Another common cause of rod bearing failure is inadequate oil levels. Low oil levels can adversely affect any type of bearing, whether main bearings or rod bearings.

Insufficient lubrication can lead to increased wear within the engine. This is because oil not only lubricates the bearings but also helps dissipate heat.

Without proper oil flow to the crankshaft, the bearings become dry, resulting in friction between them and the crankshaft. This friction causes significant wear to both the bearings and the crankshaft.

Infrequent Oil Changes

The final probable cause of rod bearing failure and the associated cost to replace engine bearings is infrequent oil changes.

Inadequate maintenance practices are often the primary issue leading to bearing problems. Some individuals extend their oil change intervals to 20,000 miles, even though it’s recommended to do so every 10,000 miles or less.

In such cases, the bearings tend to wear out much faster than normal. This is primarily due to the engine oil not fulfilling its primary function of lubrication.

What Are The Bad Rod Bearing Failure Symptoms

If your rod bearings are deteriorating, you’ll likely hear noticeable sounds before detecting other signs. However, there are additional symptoms to be aware of:

Oil Problems

When rod bearings are failing, you may experience oil-related issues. These include low oil pressure, frequent oil changes due to contamination, or the presence of metal shavings or a silver sheen in the oil.

Modern engines employ sealed systems where bearings operate submerged in fluid to reduce friction and prevent bearing failure. If problems arise, you may observe oil with shavings, thinning due to gas contamination, or low oil pressure.

Noisy Engine

Failing rod bearings produce distinctive knocking sounds, hence the term “engine knocking.” These noises become noticeable as the engine cycles on and off, and in severe cases, even when idling.

If you hear a metallic knocking sound, it’s often a sign of problems and you should then prepare for the upcoming rod bearings replacement cost.

Transmission Issues

Grinding in the transmission or frequent belt wear can be linked to rod bearing problems. As the rods fail to smoothly transfer force to the crankshaft, it places increased pressure and tension on the transmission.

Engine Failure

Rod bearing issues can lead to engine failure, with instances like a rod piercing the crankcase being a common cause. In such cases, you’ll need to consider whether repairing the engine is worthwhile or if replacing the short block is a more cost-effective solution.

These symptoms serve as indicators of potential rod bearing issues, prompting the need for timely inspection and repairs to prevent further damage to your engine.

FAQs on Rod Bearings Replacement

1. Can I replace just one rod bearing, or do I need to replace all of them?

It’s recommended to replace all rod bearings at once, even if only one appears damaged or worn. Replacing all ensures consistent performance and prevents future issues.

2. Can I use aftermarket rod bearings, or should I stick with OEM parts?

While aftermarket rod bearings are available and may be more budget-friendly, using OEM (original equipment manufacturer) parts is often recommended for optimal engine performance and longevity.

3. How can I prevent rod bearing issues in the future?

Regular maintenance, including oil changes, using high-quality engine oil, and avoiding excessive engine strain, can help prolong the life of your rod bearings and prevent future problems.

4. Can rod bearing replacement improve engine performance?

Replacing worn rod bearings can restore proper engine function and improve performance by reducing friction and ensuring smooth crankshaft rotation.

5. Are there any warranties on rod bearing replacement parts or labor?

Warranties may vary by the manufacturer or repair shop. It’s recommended to inquire about warranty coverage for both parts and labor when scheduling the replacement.

6. Is it possible to upgrade rod bearings during replacement for better durability?

You can choose upgraded or performance-oriented rod bearings during replacement to enhance durability and performance, depending on your needs and budget.

Check out this video from NAS PERFORMANCE to learn how to change rod bearings with the motor still in car!

Conclusion

In conclusion, understanding the rod bearings replacement cost and the factors influencing it is essential for responsible vehicle ownership.

While the cost can vary based on multiple factors, including vehicle make and model, labor rates, and the choice between OEM and aftermarket parts, one thing remains clear: addressing worn or damaged rod bearings is crucial to prevent more extensive engine damage and costly repairs down the road.