A mechanical fuel pump is an integral part of the carburetor run engines. Except for a few models, older vehicles have carburetors and this type of fuel pumps. Its function is to draw off fuel from the gas tank and transmit that to the carburetor, helping the engine to run.

If you have an older car, the fuel pump in it may show some problems over time. Find out how to check the pump for possible issues and the safe ways to replace it.

Contents

The Problems of Mechanical Fuel Pumps

The fuel pumps found on classic cars are highly reliable. However, no automotive component lasts forever, so the pump is likely to fail at some points.

Following are the symptoms of a failing pump in an old engine:

Vapor Lock

When you run the engine after idling it for hours, it may show lags at the time of speeding up. This behavior along with a few others, including no discharge from the accelerator pump, low or no fuel pressure, and dry carburetor air horn, indicates that the fuel pump is having a particular problem known as vapor lock.

Vapor lock happens when the liquid in the internal combustion engine vaporizes in the fuel delivery system, interrupting the fuel flow through the fuel line and other pipes. These vapor lock symptoms may occur during driving on a blazing hot day.

Fuel Foaming

Another mechanical fuel pump problem that affects engine performance. It makes the engine jerking or lagging in a repeated manner.

A Leak in the Pump

A leak in the pump’s valve or diaphragm drops fuel pressure and due to the lack of enough fuel, the carburetor does not get a sufficient amount of gas. The result is a misfiring, stalling, or lagging engine. It can also run lean due to the less amount of fuel in the air-to-fuel mixture.

How to Check a Mechanical Fuel Pump

There are several ways to check these pumps. You can use any of these four methods:

Method 1 — Visual Inspection

A visual checking should be enough to find out if there is any dripping fuel coming out of the pump. If yes, you need to replace the pump because such drippings indicate the failure of the internal diaphragm.

Never smoke or keep anything flaming near the fuel pump because it may ignite the leaked fuel. In fact, you should keep away all types of sparks from the workplace while working on an automobile.

Method 2 — Air Cleaner Removal

Removing this part allows you to peek into the carburetor. Pump the throttle linkage to see if any fuel is spritzing to the carburetor. If yes, the pump is working; if not, you will need a new pump.

Method 3 — Disconnecting the Fuel Line

Detach the fuel line from the carburetor and put that open end into a canister. A functioning pump will send jets of fuel through that line when you start the engine. Weak spurts or no fuel means there is something wrong with the pump, fuel filter, fuel line, or fuel level in the tank.

Method 4 — Checking Fuel Pump Pressure

Attach a pressure gauge to the pump exit and record the readings after kicking off the engine. Low or no pressure indicates a bad pump.

SEE MORE

How to Replace a Mechanical Fuel Pump

A failed pump needs to be changed for restoring the engine to its working state. Follow these steps to do the replacement (don’t attempt this DIY if you are a complete novice).

Remove the pump.

Disconnect the fuel pump from everything, including the fuel inlet and outline lines. Put a plug into the inlet fuel line to stop fuel leaking. Detach the two bolts that connect the fuel pump to the engine. This will remove the pump completely from its housing.

Change the gasket.

There should be a gasket where the pump mounts on the engine. Remove it carefully so that the dirt on its body does not fall off into the engine opening. Clean the mounting surface and then install a new gasket. To make sure there is no leak, apply gasket sealer.

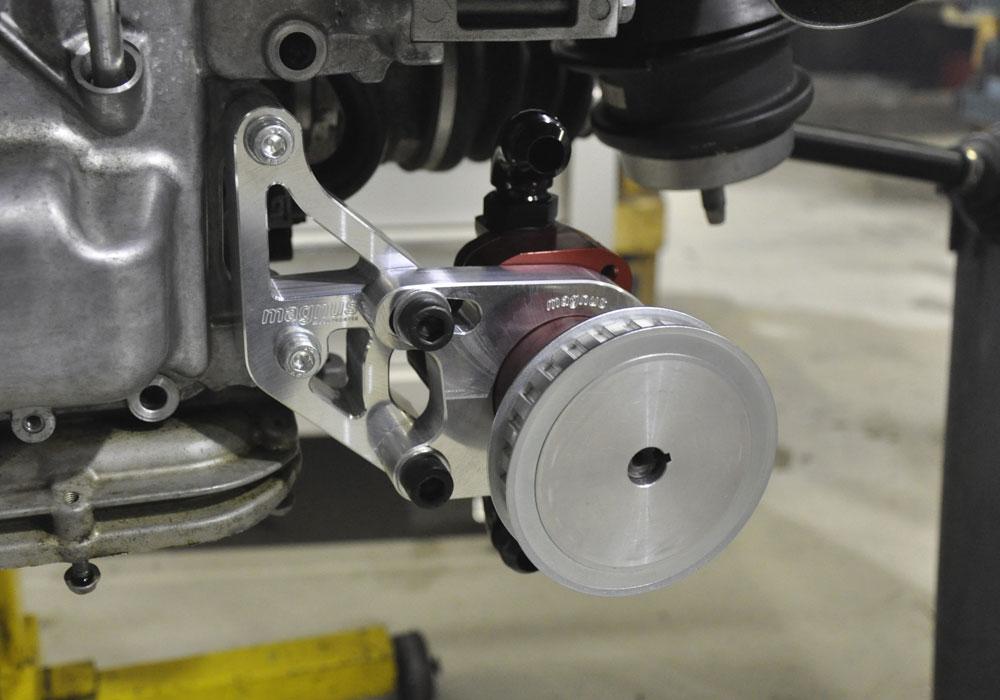

Install the new pump.

This is the step to install the new mechanical fuel pump. Before mounting it on the engine opening, treat the pump lever’s tip with grease. Attach the bolts and reconnect the lines. It’s also necessary to replace the fuel filter because you will face several problems if it’s clogged. At the same time, inspect the gas tank to find any rust or deposits. Changing it would be a wise move if it’s in a bad shape.

Run the engine.

Now, it’s time to see whether or not you have done the job right. Start the engine. It should run with no issue if the installation is successful.