Replacing rusted brake lines is a little bit tricky. How to make this work become easier, let’s dive deep into our article to know the step by steps to change your car brake lines when they get rusty and have knowledge about this small part.

Contents

Car Brake Lines: Working Principle

While car brake lines are not the most noticeable parts in the braking system and rarely get much attention, they play a key role in the function and performance of the car brake. And it can directly affect your road safety. What are brake lines on a car? Brake lines are designed with the function of connecting the brake system and running the length of your car.

Another important function is converting the impact force from the pedal into stopping power. You can simply understand that when you step on the pedal, the force from your foot will be transferred to the brake system through the brake lines. This system uses brake fluid to apply pressure to the brake calipers, creating friction between the rotor and the brake pads. A car slows down and then stopping happens when the brake calipers grip the brake system.

Most cars today often use hydraulic brakes. That means using fluid to transfer force from the foot to the brake and make your car stop. In this case, brake lines will have the responsibility to carry the brake fluid which is stored in a master cylinder to other parts of your brake system so it means the brake system will not operate without brake lines. From there, we are sure you knew the importance of this part and why you need to maintain and check the brake lines like other important parts in your car.

Why Are Brake Lines Rusted?

Rust is one of the common problems of many means of vehicle. Corrosion (oxidation) can happen to metal or rubber and even plastic. It’s basically oxygen and other elements in the environment that attack the car’s parts. As we know, brake lines are made mainly of metal (steel tubing or stainless steel) that is always covered with plastic to prevent corrosion. In terms of materials, brake lines are considered one of the most easily corroded parts on cars and they can be deteriorated naturally by heat and moisture.

According to the structure, the brake line is designed under the car, this is where it comes into contact with dirt (salt). Brake lines can be rusted by the salt that is spread on icy roads in cold weather. These factors mixed with moisture will accelerate the corrosion process.

Besides, the main cause of rust in brake lines is abrasion. Rusted brake lines are a sign that the outer protective layer has been damaged. Corrosion causes a change in the surface of the material and eventually metal erosion. For vehicles that have been used for a long time, the protective coating of the brake line (plastic) is easily worn by dirt and collision. When this layer is disabled, the brake line will be in direct contact with the air and external substances, causing serious rust.

>> Read more: How To Remove Rusted Exhaust Bolts From Your Car?

What Happens If Your Brake Lines Are Rusted?

When brake lines are corroded, this will affect the function of your brake system? Brake lines are rusted, is it dangerous? We can affirm that rusted or damaged brake lines can be a potential risk when you are behind the wheel and it can even make your brake system fail completely. Corrosion on the brake lines is one of the main killers of leaking fluid. When the brake line rust is in the worst state, it will be prone to break causing it to leak brake fluid.

Once you step on the pedal, the pressure will transfer the brake fluid via the lines and activate the brake calipers. When the brake lines broke, the fluid leaked out and didn’t have enough pressure for the calipers. Of course, in this situation, the braking action will not happen and you already know the consequence when your car suddenly loses the ability to slow down and stop.

Many drivers share with us: if my brake lines are rusted so how to fix a brake line? And our answer is: Depending on the rust condition of the brake line, we will take appropriate measures but brake line replacement can be the best method. However, how to do this? The question will be explained in the next part.

Replacing Rusted Brake Lines: 5 Simple Steps

Before starting to replace rusted brake lines, you need to prepare some necessary tools for this process if you decided to repair it by yourself:

- New brake lines

- Flare nut wrenches

- Flaring tool kit

- Bending pliers

- Brake fluid

- Tubing cutter

- A debugging tool

Step 1: Remove rusted brake lines

To facilitate the replacement process, the first step, you should jack up your car and make sure to fix all 4 corners on the jack. Metal brake lines run from the frame to the master cylinders. If the brake fluid is leaking near a wheel, you need to remove the wheel where you’ll be replacing a line.

After that, you will start to inspect every part of the brake lines to locate the line that has corroded. In this step, we recommend that you wear safety glasses to prevent debris from entering your eyes during inspection and replacement because dirt from rust stains can affect your eyes.

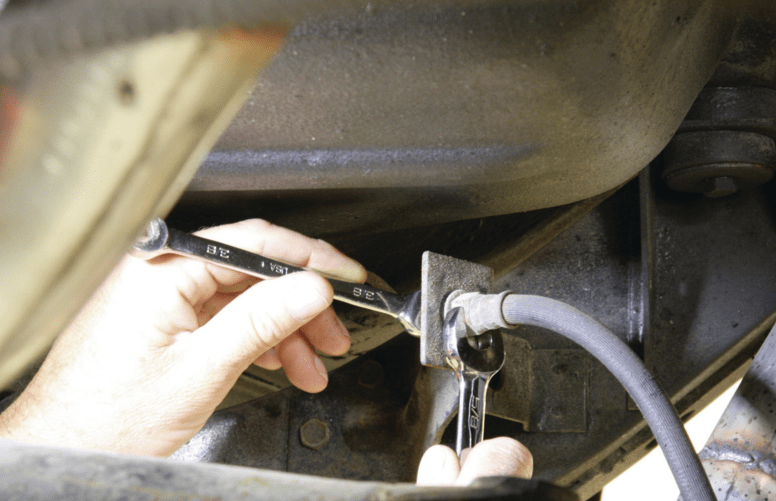

Use a wrench to unscrew both ends of the brake line. If the nuts are rusted, you can spray some oil on them to make the process easier. You should have a rag ready to wipe up any spilled liquid. As brake fluid is corrosive and can damage paintwork, clean it up immediately in case it leaks.

If you want to replace the whole line, you can use the line wrenches to remove the brake lines. you just need to cut the section of the line and use a mini tubing cutter to remove the rusted brake line section. In the process of removing the rusty brake line, you need to be careful not to mistakenly cut or loosen any other wire designed at the close of the brake line. In case you want to replace the entire brake line, you can use a flathead screwdriver to remove this brake line.

Step 2: Prepare the new lines

First and foremost, you need to know exactly the length of the old brake lines, you can use a ruler or a measuring tape to do this and the notice in this step is you should careful with the bend to make sure to have the accurate result.

Use the cutting tools to cut the new brake line into the required lengths. Don’t cut your line too short, you should leave about 1/4 inch left over to allow for flaring. Take your time and turn the knob on the tubing cutter one quarter to haft a turn at a time until the blade just touches the metal. You may have to do this many times up until the cut is complete.

Step 3: Bend the new brake lines

How to blend the new brake lines and can you do it by hand? You can bend the new brake line based on the old line simulation. And do some light bends in the new lines by hand. Depending on the material of the brake line. If the brake line is made of copper or some tough materials. You can use a machine to bend it for major bends like 90 degrees. Before bending, you need to slide a new fitting onto the line. After that use crimping pliers to make the first bend. Match the old brake line and the new line put the bender in place and start bending.

Step 4: Flare the new brake line

Remember that you should put on the fitting carefully before flaring the new brake line up to the point where it is attached and clamp it. Go on with the frame and reattach at the bottom end first, then remove your plug and reattach it there. In this step, you must make sure the fitting is in accordance with the manufacturer’s specifications.

The fitting must be slid into the line before you place the line onto the fare. Because you can’t fit the coupler when the contour is flared.

You need to choose a suitable adapter to match the size of the brake line. If you read the instructions, they will show that the adapter has a couple of humps on it. After locating the humps we will line up the adapter and the brake line with the first hump. Then we can go ahead and close up our clamps.

Note that: you should tighten the clamp or the brake line will slip. Insert the pin end into the brake line and insert the cone tool to push the die into place, forming a line, the cone will have a recess where it rests on the die. Fasten the cone tool until it stops, remove the mold, and reinsert the cone tool so that the flare can be folded down. Squeeze until it stops.

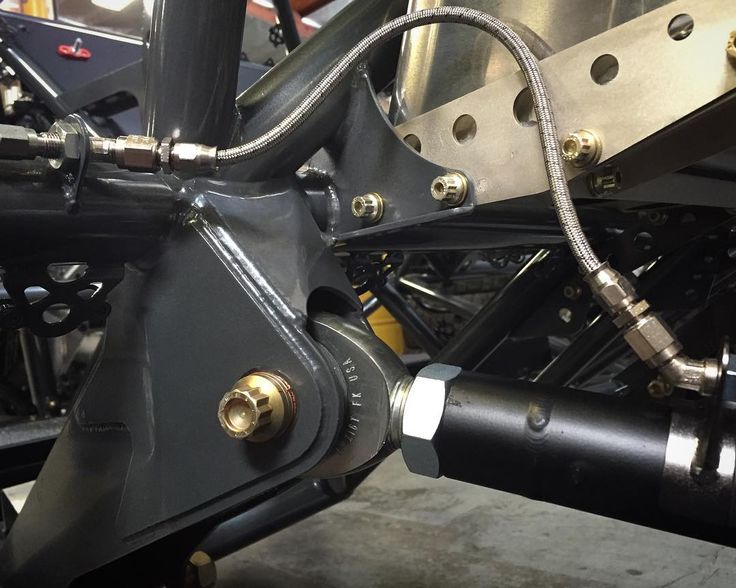

Step 5: Install the new brake line

In this step, you will connect the new brake line part to the coupler, and match the old and new lines with an adapter. Hold the link with an open-ended wrench and tighten each joint with a flare wrench.

With the 5 steps we have analyzed above, do think the rusty brake line repair will be easy for you? So “How long does it take to replace brake lines?” Replacing rusted brake lines is always a quick process. It just takes you about 1 or 2 hours depending on your experience.

How To Protect Brake Lines From Corrosion?

It’s easy to make your brake lines get rusted, so how to keep this part always in good condition? Normally, brake lines are designed with a lifespan just as long as the car does. However, the function of the brake lines also depends on the environment when you live in the “cold climate”. To prevent the lines from rusting, we will share with you some tips:

- You can coat the brake line with anti-rust or spray paint just to keep them from rusting. If your brake lines were made of steel and don’t have a plastic or rubber coating. It would be a great idea if you use stainless steel or nickel-copper instead of steel for brake lines. Because nickel-copper is anti-corrosion and it won’t rust and can last for very long. Before you apply the paint or rust extender, you can clean the dirt on the line by using alcohol.

- Take the car to the service center to check the underbody for rust periodically. Undercarriages should be washed and clean during the winter for one very simple reason: to remove the corrosive salts from the road. In the event of severe corrosion of the brake lines. NHTSA’s advice to drivers is to replace the entire brake hose assembly.

- You can limit the rusted brake lines by changing the brake fluid periodically (every two years or sooner). The reason is that brake fluid accumulates deposition over time. This causes the inside of the brake lines to also corrode.

>> Related Post: How To Make Car Brakes Last Longer?

Wrapping up: Replacing Rusted Brake Lines

Brake lines are steel or copper tubing that carries brake fluid from the master cylinder to ABS units, equalization valves, calipers, and wheel cylinders. Brake lines wear out over time, steel lines corrode, and eventually crack. And when the brake lines are defective, it can make you have to replace the entire brake system. And most importantly it can directly affect your safety and your passengers.

Any car can blow a brake line. However, it happens more commonly in road salt or when your brakes are made of steel. Therefore, to ensure that the brake lines are always in the best condition. You should check them regularly, especially in winter weather. To end this topic we want to affirm that: the brake line is a very important part. If you notice any signs of rusted brake lines, don’t delay fixing or replacing them.