So what are the pros and cons of drilled and slotted rotors? Let’s follow along with Car From Japan.

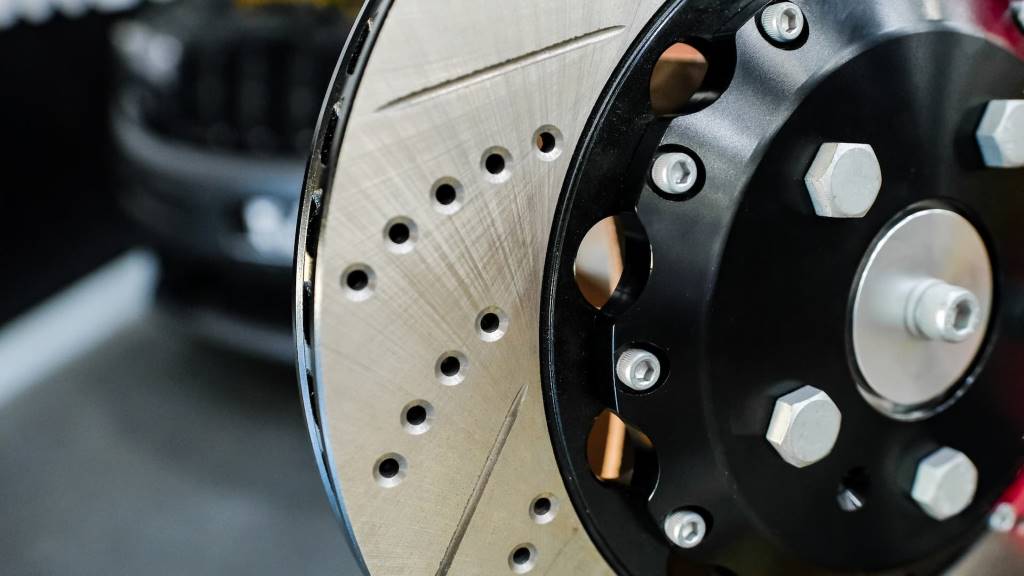

The drilled and slotted rotor is a type of brake rotor designed to improve the braking performance of the vehicle. The rotors have holes and grooves drilled into them, which increases the surface area and improves ventilation for the rotor. This can help dissipate heat more efficiently and provide better braking performance.

These rotors have been well-aware for a while, but they’ve become increasingly popular lately. Initially, they were mainly used in racing cars and high-performance cars. The first drilled and slotted rotors were made of cast iron. But with technological advancements, they are now made of more efficient materials such as carbon ceramics, composites, and aluminum. These rotors have been used in auto racing for over a century. And over time, the technology has evolved and they are now available to vehicles for everyday use.

Contents

Pros and Cons of Drilled and Slotted Rotors

Below are pros and cons of drilled and slotted rotors for your reference.

Pros of Drilled and Slotted Rotors

Improved braking performance

Drilled and slotted rotors offer more-than-you-ever-asked driving performance thanks to their effects of increased surface area and ventilation. The bores and grooves on the rotor increase the surface area, allowing more friction between the brake pads and the rotor. This additional friction improves the vehicle’s braking performance.

Drilling holes and grooves on them also allow for better heat dissipation. Temperature is one of the biggest enemies of brake performance, as it can cause the brakes to blur or lose braking power. They can provide better and more stable braking performance by dissipating heat generated during braking.

Increased heat dissipation

Holes and slots are drilled into the surface of the fan blades for more efficient heat dissipation. This increased ventilation on the rotor allows hot air to escape and cooler air to enter the rotor. This helps reduce the temperature of the rotor and brake pads, preventing them from overheating and warping.

Improved braking in wet weather

Holes and grooves drilled in the rotor surface can direct water away from the braking surface. When driving in rainy weather, water can accumulate on the brake rotor, reducing friction between the brake pads and the rotor. This can reduce braking force, improving braking performance in wet weather. With better wet-weather braking, vehicle owners can enjoy a safer and more comfortable driving experience in the rain.

Enhancing aesthetics

Drilled and grooved rotors can give the vehicle a sportier appearance, which can enhance its overall aesthetic appearance. The holes and grooves drilled on the rotor can give the car a sport look and high performance. This can be especially appealing to car owners who want to personalize and enhance the look of their vehicles. Overall, they can be a way to differentiate and make the car look more unique.

Increased stopping ability

Due to the improved design and ventilation system, the drilled and slotted rotors have better-stopping ability than conventional types. The bores and grooves on the rotor increase the surface area, allowing more friction between the brake pads and the rotor. This additional friction improves the vehicle’s braking performance.

Drilled and slotted rotors also allow for better heat dissipation. This keeps the rotor and brake pads cooler, preventing the brake pads from overheating and losing stopping power. This can significantly affect the stopping power of the vehicle, especially in high-performance or high-speed driving conditions.

Better performance on high-speed vehicles

The rotors can perform better in high-speed and high-performance driving conditions. Due to improved ventilation and design, the drilled and slotted rotors can handle higher temperatures and braking loads than conventional rotors.

They can also help improve the vehicle’s braking performance in high-speed conditions, providing a safer and more enjoyable ride.

Extends brake pad life

Improved ventilation of drilled and slotted rotors can help extend the life of brake pads. Drilled and slotted rotors can reduce brake pad wear by dissipating heat generated during braking.

In addition, the increased surface area of the rotor gives the brake pads more room to clamp the rotor, resulting in a more even distribution of brake pressure. This can help avoid wear and tear on the brake pads. With a longer brake pad life, vehicle owners can save time and money on brake pad replacement costs.

Reduce vibration

Drilled and slotted rotor design reduces vibration during braking, providing a better driving feel. Slotted or drilled holes will disperse heat, reducing the annoyed vibration created during braking.

Additionally, the increased surface area of the rotor can help to distribute brake pressure more evenly, which can also help reduce vibrations. This can result in a smoother and more comfortable driving experience.

Easy to clean

Drilled holes and slots make it easier to clean brake dust, rust, and other contaminants. Drilled holes and slots can help remove dirt and brake debris. As they are much easier to clean than conventional rotors, which can be quite challenging as brake dust and dirt can accumulate on the rotor surface. This can help keep the rotor surface clean and prolong the life of the rotor.

Better durability

The design of the drilled and slotted rotors makes them more durable and more resistant to wear. The increased surface area of the rotor can help to distribute brake pressure more evenly, which can help prevent rotor wear.

In addition, the improved ventilation of the drilled and slotted rotors can prevent the rotor from warping and cracking, which can prolong its life of the rotor.

Reduce brake fading

Drilled and slotted rotors provide better cooling, which can reduce brake fading during high-performance driving. The rotor can become very hot when running at high speeds or in high-performance conditions, and this can cause the brake pads to lose friction with the rotor and cause the brakes to blur.

The fan blades are drilled and grooved for better ventilation, can dissipate heat more efficiently, and can reduce brake fading. This can result in a safer and more enjoyable driving experience.

Better resistance to warping

Due to the design of the drilled and slotted rotors, they are less prone to warping or cracking under high temperatures and heavy use. Increased ventilation of the drilled and slotted rotor can provide more efficient heat dissipation, preventing the rotor from warping and cracking.

Additionally, the increased surface area of the rotor can help distribute brake pressure more evenly, which can also help prevent warping and cracking.

Cons of Drilled and Slotted Rotors

Noise

Drilled and slotted rotors can make more noise than standard rotors, especially when braking at high speeds. The drilled and slotted design can cause the brake pads to vibrate more, resulting in a noticeable squeal or squeal.

Compatibility issues

Drilled and slotted rotors are not compatible with all vehicles and braking systems. It is essential to check the compatibility of drilled and slotted rotors with the specific make and model of the vehicle before purchasing and installing them. Additionally, drilled and slotted rotors may require specific type of brake pads and systems to function correctly.

Reduce brake feel

Drilled and grooved brake discs can negatively affect the “feel” of the brake pedal. Designs with holes and grooves can cause the brake pedal to have less resistance, making it difficult for the driver to accurately measure the braking force applied. This can lead to a less safe and less accurate driving experience.

More heat

Drilled and slotted rotors can generate more heat than standard rotors, resulting in increased brake fading. This is because the bore and groove design can cause the brake pads to overheat more effectively, which can cause the brake pads to lose their ability to grip the rotor and reduce overall braking force. This can be especially difficult when driving at high speeds or in emergency braking situations.

Reduce fuel efficiency

Drilled and slotted rotors can negatively affect fuel efficiency. This kind of rotor design pushes the brake pads to create more drag, causing the vehicle to consume more fuel to maintain regular speed. The cons affect vehicles frequently on highways or over long distances.

Reduce resale value

Drilled and slotted rotors can negatively affect a vehicle’s resale value. Slotted designs are often seen as performance upgrades, making a vehicle less appealing to potential buyers who aren’t interested in a performance upgrade.

Not only that, additional wear and tear due to drilled and slotted rotors can negatively impact the vehicle’s resale value.

Reduce stopping force

Drilled and slotted rotors can reduce the overall stopping force of the vehicle’s braking system. Hole-and-groove designs can put extra pressure on rotors and brake pads, which can cause them to wear out faster, reducing their effectiveness. This can be especially difficult in emergency braking situations, where maximum stopping force is required.

Need more maintenance

You may not know but drilled and slotted rotors need more maintenance to behave as typically as classic ones. Their designs, with holes and grooves, can create more dust and debris, clogging brake pads and causing them to wear out faster.

In addition, the design can cause the blades to rust faster, requiring more frequent cleaning and anti-rust.

Reduce comfort

Drilled and grooved brake discs can reduce the overall comfort of your vehicle’s braking system. The drill and slotted design can produce more noise and vibration, which can be transmitted through the brake pedal, causing discomfort to the driver and passengers.

Reduce safety

Drilled and slotted rotors can reduce the overall safety of the vehicle’s braking system. Drilling and slotting designs can cause brake pads to wear out faster, reducing their effectiveness and potentially increasing the vehicle’s stopping distance. A design with bores and grooves can more effectively cause the rotor to crack or warp, resulting in brake failure.

Conclusion

We have scrolled through some pros and cons of drilled and slotted rotors. Hope this will help you to decide your every needed step with this type of rotor and always be aware of proper ways to maintain your car.

For more helpful Car maintenance tips for your every future project, follow Car From Japan today.