The idle air control (IAC) valve’s primary function is to manage the engine’s idle speed and keep it within a normal RPM range. If this valve malfunctions, it can throw the air supply off and adversely affect the engine’s performance.

Let’s explore the most common bad idle air control valve symptoms, what you can do about it to get the IAC properly working.

Contents

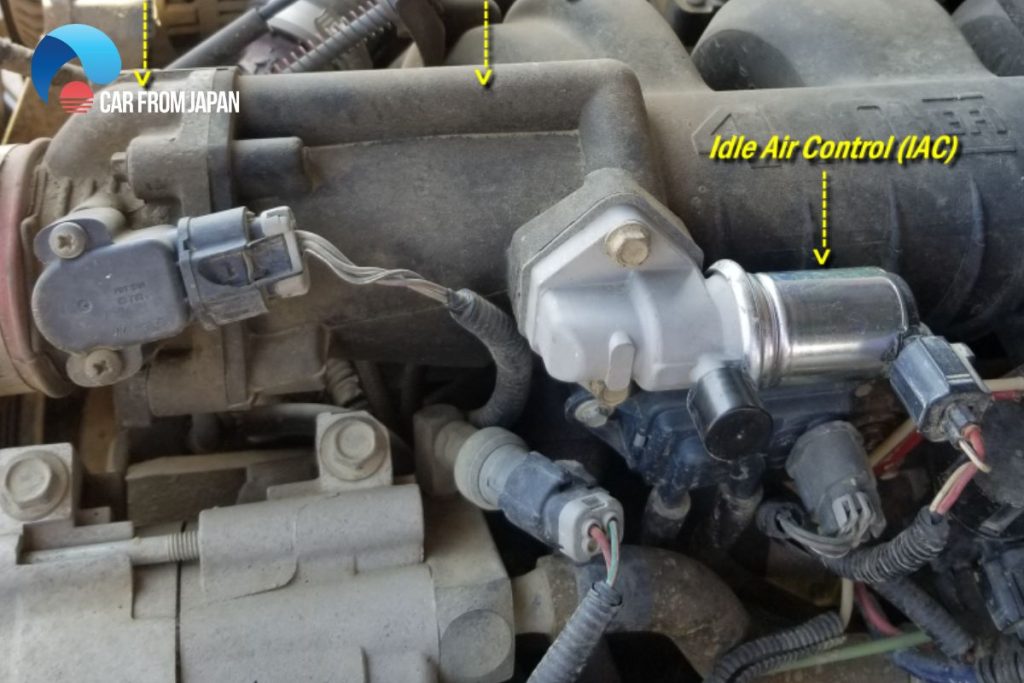

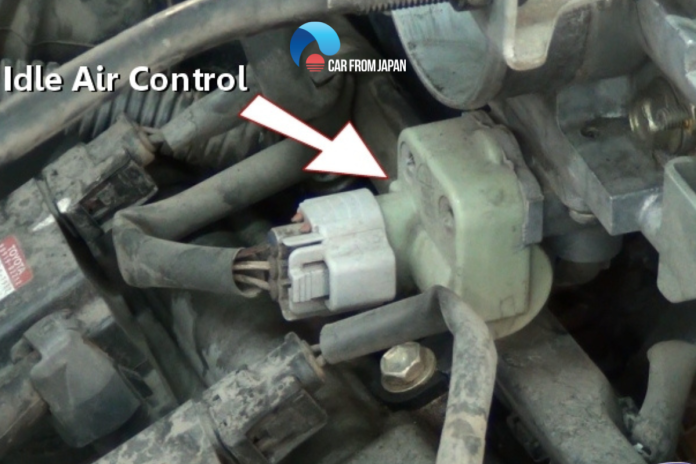

An Idle Air Control Valve: A Closer Look

An idle air control valve is found on most fuel-injected engines without electronic throttle bodies. Most new cars these days come with electronic throttle control (ETC), which eliminates the need for an idle air control valve.

That said, there are still plenty of IAC-equipped vehicles on the road, and knowing bad idle air control valve symptoms is still a basic car DIY maintenance tip.

What does an idle air control valve do in your car? Located on the throttle body of fuel-injected engines, the idle air control valve or IAC valve works with the vehicle’s ECU to regulate the amount of air coming into the engine while stationary to ensure smooth idling.

Imagine the throttle plate as a door to your engine. The IACV is a small window next to the door. When the engine is idling, the door is mostly closed, but the window allows just enough air in to keep things running. The IACV adjusts the size of this window to maintain a steady flow of air.

Without a properly functioning IAC valve, your engine might idle too high (racing), too low (stalling), or fluctuate erratically. This can lead to a rough, uncomfortable ride and potentially damage your engine over time.

How Does An Idle Control Valve Work?

Please be noted that each manufacturer designs a different type of IAC valve but they share the same operating principles. How the IAC work are divided into 4 steps.

Step 1:

The IAC valve in most cases is installed on the throttle bore to adjust the air intake into the engine at idle mode. The power control module got feedback data from sensors to command the air passage to open or close.

Remember that the valve will not be used and has nothing to do with the engine at speed over idle mode. The idle speed of the engine is designed to be constant and fixed.

Step 2:

When airflow blows through the IAC valve, the volume of air will be adjusted by the opened/closed ports inside the valve. These ports are sealed by a gasket to prevent air leaks. Some valves have a part using coolant to cool down the air at 85 Celsius degrees to improve the air intake volume.

Step 3:

When the IAC valve is running, the airflow bypasses the valve through the passage in front of the butterfly. Then it comes into the throttle bore by the passage next to that, at this time the butterfly is closing completely.

Step 4:

Due to the regular huge volume of air passing through the valve, a condition called coking augments and hampers the operation of the valve. Therefore, cleaning the valve periodically is a must to avoid idle air control valve symptoms.

What Happens When The Idle Air Control Valve Goes Bad?

When the idle control valve malfunctions or fails, it will make the engine work less efficiently and thus can cause all sorts of issues with the vehicle. Usually, a bad idle air control valve will produce various telltale signs that will alert you early on of an engine-related issue. Although rare, in some cases, a faulty valve may even render the car undrivable.

Technically, you can still drive with a bad IAC, but driving with a bad idle air control valve is not recommended. It can commonly lead to engine stalling, which can compromise vehicle safety. Furthermore, note that you won’t pass a state emissions test if the check engine light is on due to a faulty valve.

Bad Idle Air Control Valve Symptoms

Having understood the way the IAC valve works, it would be much easier for us to get to know the nature of some symptoms that call for an idle air control valve, which are:

Irregular/fluctuating idle speed

The most direct and common idle air control valve symptoms are irregular and/or fluctuating idle speed. The idle air control valve manages the idle speed of a car engine.

It is programmed to regulate and maintain a constant engine idle speed, and a faulty idle air control valve will not be able to control the speed anymore. This will result in abnormally high or low idle speed, or in some cases, the idle speed will repeatedly climb and fall.

For your information, the regular idle speed of a passenger car engine is between 600 and 1000 RPM, while that for medium and heavy-duty trucks is approximately 600 RPM.

Engine stalling

Stalling or freezing of the engine is another common idle air control valve symptom. Your engine requires an optimal amount of air and fuel mixture to run efficiently. If the idle air control valve fails, your engine won’t get its much-needed source of air to maintain a proper idle. The result is the air-starved engine might stall while operating, and in some cases, the engine might not idle at all, and stall as soon as it is started.

You will not be able to drive the car if stalling happens. This is because the whole valve system will malfunction just after starting the ignition.

Engine stalling when overloaded

There is another reason for the engine stall. When the IAC valve has already malfunctioned, the engine can still run but will bear an increase in load. Then if the driver turns on the heater or air conditioner, the engine may become overloaded and come to a halt at once. Another sign to look for is the steering wheel dragged to one side.

To get on the road again, the first aid steps are to turn off the heater or air conditioner, wait for a few minutes, and then the cooled engine can be turned on again.

Engine Won’t Start: While engine stalling is a common telltale sign, sometimes a faulty IAC can throw off the air and fuel mixture enough that the engine might not be able to start at all, although this is quite rare.

More force on the brake pedal

At idle speed when no foot force is applied on the accelerator, we all know that braking is very subtle to prevent any forward motion. Any excessive effort on the brake to keep the car standing still at a red light could be the symptoms of a bad IAC valve.

This is due to the engine idling faster than normal, and thus the car is running at a faster idle speed. As an additional sign in idle air control valve symptoms, drivers can also try to listen to the sound of the idling engine to see if it is spinning strangely fast and harshly, which is also a good way to help clarify the feel on the brake foot.

Rougher rides

An intact, healthy idle air control valve will allow the engine to operate at peak efficiency and thus will smoothen the rides. But a damaged valve can result in fluctuations and vibrations causing the vehicle to stop at once. This is because less air will pass through the valve and the engine will start shaking vigorously.

Warning light for checking engine

If the engine control module detects an issue with the idle air control valve circuit or signal, for instance, it notices the varying number of revolutions per minute, it will activate the Check Engine warning light on the dashboard.

Of course, a whole host of issues can set off the Check Engine Light, so you should have the computer scanned for trouble codes to narrow down the culprit, even in the case that the Check Engine light is illuminated together with other bad idle air control valve symptoms above.

Bad Idle Air Control Valve: Ways to Troubleshoot

This section is just for mechanical reference only, we advise you to take your car to a professional garage for quality check-up services. However, for whoever is confident enough to experiment with their cars and for any mechanic apprentices, we hope these three ways will be of great help.

Vacuum leaks and circuit problems can have very similar symptoms to those of a bad IAC valve. That’s why before you rush out and buy a new valve for replacement, it’s a good idea to test your unit to see if it’s the culprit.

If you have an OEM-level scanner

Here, it’s worth pointing out that an OEM-level scanner is the easiest way to test an idle air control valve since it’s designed with most of the same functions as the dealer’s factory code scanner. Meanwhile, regular onboard diagnostics OBD-II scanners and code readers don’t have the necessary bi-directional controls to test an IAC.

OEM-level scan tools are the fastest, easiest way to test an IAC valve because, on many vehicles, you can directly control the IAC. This means this will take the powertrain control module (PCM), which is what monitors the IAC, completely out of the loop.

As you incrementally open the valve using the OEM scanner, you should see the idle speed increase and as you close the valve, it should decrease. If the IAC does not respond as such to the scanner’s commands, the issue is either the valve or its control circuit.

That said, you might not have access to an OEM-level scan tool, so in this article, you will learn how to troubleshoot a faulty IAC valve using a regular code reader and a digital multimeter.

Read the error codes

If you’ve been experiencing one or more idle air control valve symptoms, get a code scanner to the port under the dashboard to bring up the error codes that make the engine warning light turn on. Look up the description of the code to find out the reason.

In most cases, vehicles made after 1996 that come with OBD-II will set a code for a faulty idle air control valve. Older cars with the earlier OBD-I will also set a Diagnostic Trouble Code for a bad IAC. Nowadays, for utmost convenience, you can even get an inexpensive code reader for your smartphone.

Once you’ve read the code, start the engine and note down the settled idle speed. Shut off the car, remove the car key, open the hood find the Idle Control Motor in the valve and disconnect it. Follow the instructions to disconnect the motor properly according to the car’s service manual.

Now, start the engine again and note down the settled idle speed this time. No difference between the two idle speeds means the Idle Control Motor is not working. This method confirms if there is a problem with the idle control motor, not the problem itself.

Check for vacuum leaks & check the IAC connections

As above, vacuum leaks and circuit problems can have very similar symptoms to those of a bad IAC valve, so once you find IAC codes stored, you’ll need to perform a visual inspection to rule out vacuum leaks and problematic electrical connections.

You’ll want to look for damaged hoses or other problems that might be creating vacuum leaks. Also, check that the IAC’s electrical connector is clean and tight, and check if any of the wires going to the IAC are loose or broken. Repair or replace damaged parts, then clear the codes and see whether that resolves the problem.

Check the IAC for carbon buildup

Additionally, note that an IAC can be intact electrically but faulty mechanically. That’s why while you’re at it, it’s highly recommended that you remove the IAC to check if it’s covered in excessive carbon buildup and debris.

When your idle air control valve is dirty with dust, debris, or carbon accumulation, the idling process won’t be smooth since the valve won’t be able to control the engine’s RPM efficiently. Excessive carbon buildup on an idle air control valve can even make it stick.

When this valve sticks, it might make the car idle at a very high RPM or, in most cases, make the car stall at a low RPM. Thus cleaning your idle air control valve regularly to prevent carbon and debris buildup is important.

If you let your IAC valve clog up, the more frequently you will experience engine stalling and rough idling, and the more likely you will need to replace it prematurely.

You can use a throttle body cleaner to remove contaminants in the idle air control valve to restore it to proper mechanical operations. Repair or replace damaged parts or clean the IAC if needed, then clear the codes and see whether that resolves the problem. If the issue persists, you may need to replace the IAC.

Troubleshooting based on idle speeds

A poorly idling engine may run too fast, too slow or stall. Start the engine and look at the tachometer on the dashboard.

A high engine idle:

1000 RPMs is the normal limit for idle speed. Compare the current idle speed of your car to 1000 RPMs. If it is higher than 1000 RPMs, it is too high. If you know the normal idle speed of the car, compare it with the current idle speed and it should be lower then.

A low engine idle or stalling:

Is the idle on the tachometer lower and more inconsistently than you normally feel and remember? Is the car sporadically stalled? If yes, it may be the consequence of a faulty IAC valve.

Keep an eye on the tachometer while checking idle speed. It’s time to diagnose any leaks on the vacuum lines in the engine bay for cracks or worn areas by connecting the line to a vacuum gauge to measure the level and the consistency of the vacuum or spraying a mixture of soap and water on the lines to look for bubbling at the leaking point.

If there are leaks, at the same time check the “check engine” warning light to confirm the IAC valve problem.

Detecting issues for specific makes

General Motor

Connect the negative lead of a test light to the body of the car and press the test light into each of the four circuits on the GM idle control motor. The test light should flash or go from bright to dim through each circuit while the engine is running.

- If there is no flash, the ECU is having problems instead of an idle control motor.

- If there are flashes, you need to replace the idle control motor in the valve.

Ford

Find two electrical pins on the solenoid in the idle control motor and connect an Ohm meter to measure the resistance between the two. The resistance should be between 7.0 to 13.0 ohms or else the idle control motor needs to be replaced.

Chrysler

Connect a bidirectional scan tool to the same OBD port you use to plug the code scanner into. Increase the idle speed with the scan tool. If there is no increase, the idle control motor definitely got an issue in its circuit preventing the signal from changing the idle.

Other popular makes

Other popular car models, including the Ford Ranger, Honda Civic, Chevrolet, BMW, and especially Nissan Maxima, also appear to be susceptible to this issue within the aforementioned content.

Common check-up recommendations would be to clean the valve, or else it may be the computer’s error, faulty electrical wiring or circuits, air leak, or vacuum leak.

Check the leaking problem before replacing the valve. Though replacing the valve is pricey it is quite worth all your trouble.

Learning more about symptoms of bad idle air control valve in the video:

FAQs

Can I drive with a bad idle air control valve?

It’s generally not recommended to drive with a bad IACV. While your car may still run, it will likely experience rough idling, stalling, and other performance issues. This can be dangerous and may also damage your engine over time.

What causes an idle air control valve to fail?

– Carbon buildup: Over time, carbon deposits can accumulate on the IACV, restricting its movement and affecting its ability to regulate airflow.

– Electrical problems: Wiring issues or a faulty IACV motor can prevent it from functioning properly.

– Mechanical wear and tear: The IACV is a moving part and can wear out over time.

How much does it cost to replace an idle air control valve?

Idle control valve replacement can cost between $150-$500, the cost will vary depending on the make and model of your car and the labor costs in your area. It’s not too expensive to replace this valve and most car experts advised that it’s not worth getting it fixed compared to replacing a new one.

Endnote

A malfunctioning idle air control valve can significantly impact your driving experience, leading to a range of frustrating symptoms. From rough idling and stalling to high RPMs and difficulty starting, a bad IAC valve can make your car feel unreliable and unsafe.

Knowing all of this for quick detection and temporary fix before opting for professional service and repair at the given time to enjoy those long drives for long.

Thanks for sharing my video!

Why show two pics…and neither is an Idle Control Valve.