It is normal for your car to have some problem, or when you want to add some features to your car that require soldering. Crimp terminals are efficient, work well, and are sometimes required, but corrosion can set in and cause problems with the connection over time. Knowing how to solder wires correctly is a worthwhile skill to learn because it is the best bet for a long-lasting repair. You may feel a little intimidated if you have never done that before, afraid that you will make a mess and ruin everything. Fear not, this article will solve your problem with tips and tricks and what you need to pay attention to so you can solder like a pro.

1. Safety measures

- Use safety glasses in case the solder pops or splashes so it won’t get in your eyes

- Careful around the soldering irons, it is very hot

- Do not solder around flammable materials

- Before you start, ensure you disconnect the battery before soldering, and any carpet or plastic trim is protected from molten solder if you solder inside the car. It’s best to put something non-flammable under the place you’ll work

- Work in a well-ventilated area to avoid breathing in the smoke from soldering. If not, using a fan to blow the smoke away from you

- Because we will be using lead in soldering, always clean the workplace and your hands well, especially before touching any foods

2. Choosing materials

- Choose the right types of solder that are used for electrical solder. Don’t use silver solder because it is for solder tubes and metal sheets, and its acid core will damage the plastic insulation over time

- There are lead and lead-free solder for you to choose from, but people usually prefer lead solder because it can get into wire strands better and has a lower melting point. If you don’t know the solder you using is lead or lead-free, try melting it to see: the lead one is shiny while the lead-free one is duller

- Using rosin paste flux is a great way to avoid oxidation and make your soldering much easier and last longer. Put them on the joint and let them melt before adding solder. But remember not to use the acidic one

SEE MORE:

3. Getting to work

- Careful when you strip the wire so as not to break the strands off the wires. Doing so would make it harder to solder and the wires can melt and cause a fire. If you do it by mistake, just cut the wires and strip them again. Remember to strip the same length on both wires

- The heat shrink will shrink about half of its size when heated, so choose the one that barely fits the size of your wires. Slide it on the wires BEFORE you solder, and make sure they don’t stay too close when you work because the heat may shrink them before the work is done

- You have two ways to connect the wires together. The first one is to unravel the strands, spread them a little, then intermesh the wires and twist them together. If you don’t have much room or length to do so, then you have the second way, which is to tightly twist the strands on both wires first, make an X, and twist them around each other. Either way, don’t let the end of the strands stick out because they will pierce the heat shrink and cause a short

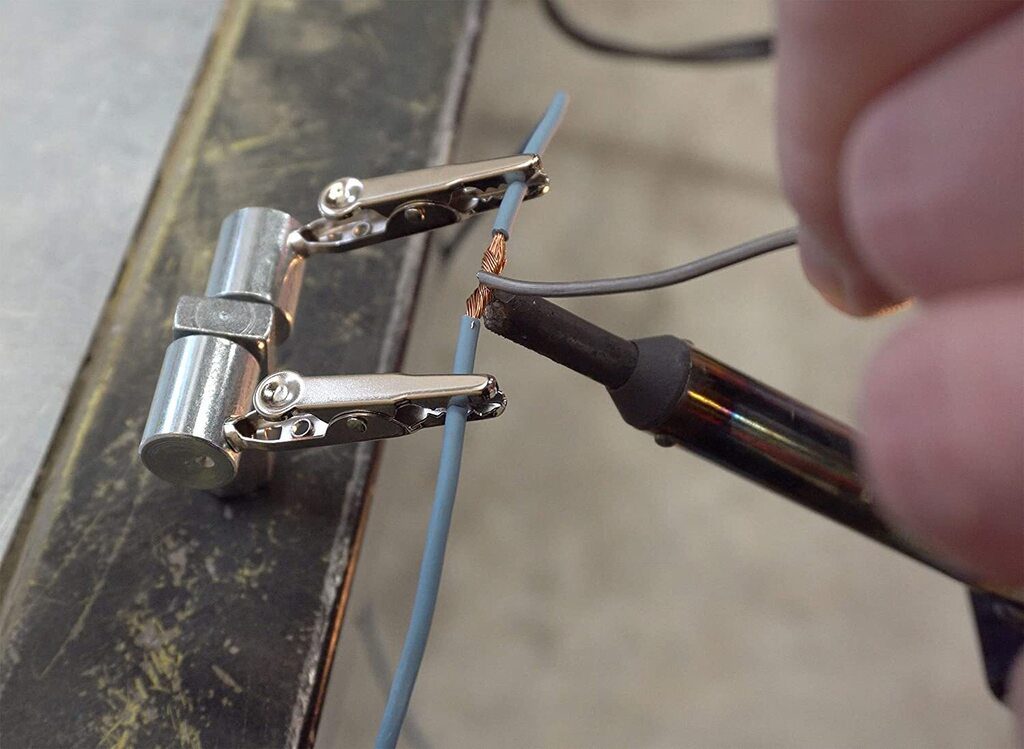

- You should use a wire holder when you work because it’ll be more steady and easier to solder. If the clip is too tight and sharp and may pierce the wire insulation, you can cover them with heat shrinks

- After you heat up the soldering gun, don’t solder right away and wipe it on a damp sponge first to remove oxidation. You should have the tip tinned, not bare, to get better heat conduction to the wires and prevent oxidation of the iron. To tin it up, just heat the gun and add a little solder on the tip, then wipe them off on the damp sponge, leaving just a thin layer of solder left

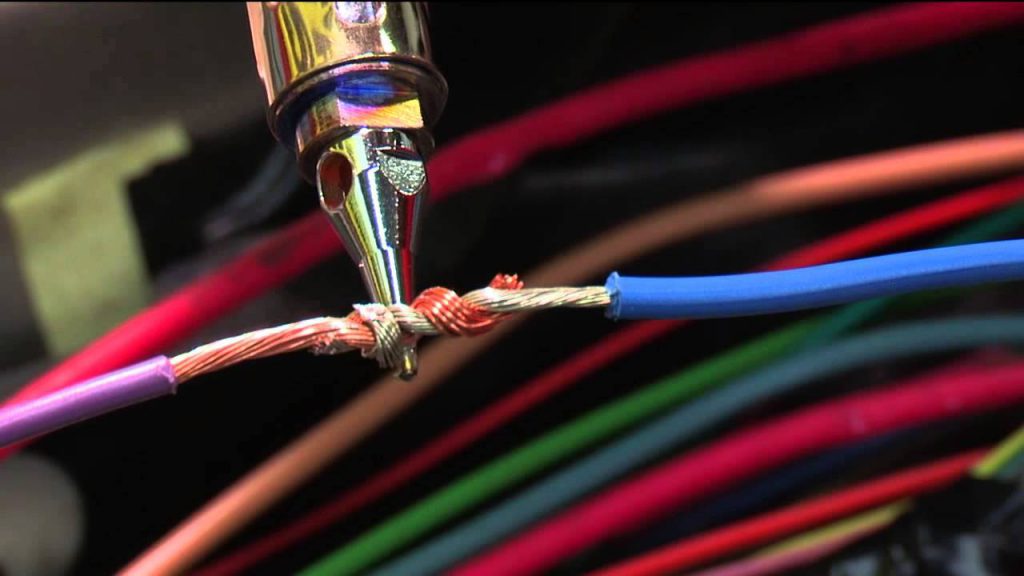

- When you start soldering, always place the gun tip UNDER the wires, and add the solder from the TOP, solder is attracted to heat, so as the solder melts, it is pulled towards the heat, through the wires, connecting every strand together with solder Adding a little solder between the tip and the wire is a good way to have better heat transfer.

- Let the wires heat up in a few seconds first, then start feeding the solder into the copper strands, let it wicked through the strands. Only add just enough to cover the strand and avoid making blobs. A good solder job should have the wires’ outline visible without any copper part exposed. Avoid making a cold solder, which is when the wires are not heated enough, so the solder only covers the outside of the wires instead of getting between them

- Always clean the soldering gun tip by wiping it on the damp sponge when the tip is still hot. It is to make sure you have a clean tip every time you work with it and to make the tip last longer and work better

- Do not touch the joint until it is completely cooled, touching it while the solder is still in liquid form will move the wires around and could create cracks or air gaps in the solder

- It is recommended that you put some silicone paste or dielectric grease on your joint before you seal everything in. It will make the solder last longer and be waterproof. After you put it on, slide the heat shrink over and start heating from the middle to outward to force out any extra silicone or grease

- Electrical tape is OK, but most people don’t use good-quality tape. If you have to use electrical tape, and sometimes you can’t avoid it, there is one specific brand and model you need- 3M Super 33 or Super 88. $1-per roll tape is junk, and absolutely should never be used on electrical connections unless it is an emergency repair. Super 33 and Super 88 are about $4-5 per roll, and it goes on, sticks to, and seals the connections without falling off four months down the road.

And that’s it, that’s how you solder wires together. It will be much easier for you now, right? If you have any more questions, check the Maintenance Tips, we have all the answers you want on keeping your car in tip-top shape!