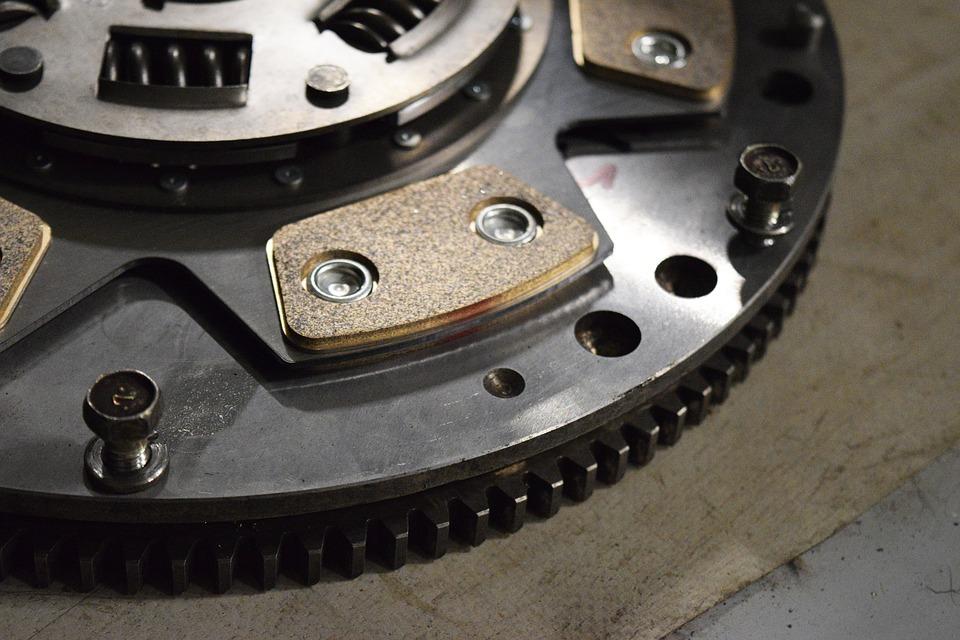

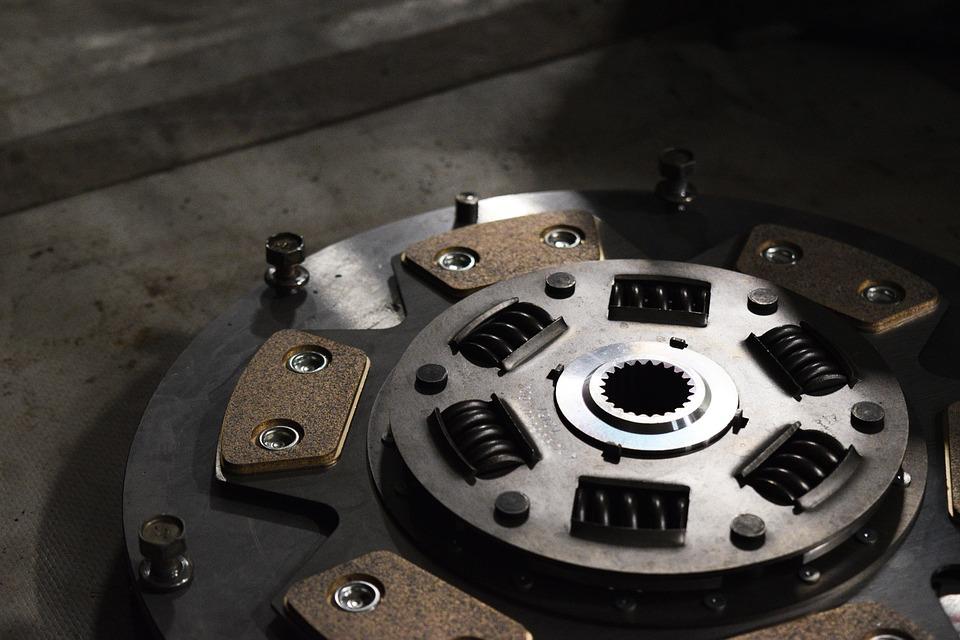

A great amount of friction is produced when the clutch disk presses with the flywheel. It grips the surface and helps to make the car move down the road. This grip starts to lose when the lining wears. Therefore, when replacing the pressure plate, people often ask, “How to resurface a flywheel?” So, let’s discuss the process!

Contents

How to Resurface a Flywheel: Complete Inspection and Resurfacing

The flywheel in a car has different purposes, including storing energy to keep the crankshaft moving and balancing the rotating assemblies.

It provides power by transmitting energy to the transmission smoothly. The clutch assembly helps the engine to provide power to the transmission.

Every flywheel needs resurfacing at some point in time. Generally, people prefer it when replacing the clutch or pressure plate. The mass of the flywheel absorbs the heat produced due to the general clutch operation.

Clutch generates more heat when it starts to slip or be abused. It could also develop cracks and blisters on the surface of the flywheel.

So, as per the expert maintenance tips, careful inspection of the flywheel is necessary to find the damages and know its condition. Outlined below are two main ways to resurface the flywheel.

Cutting the Flywheel

A brake lathe is required to begin with the cutting technique. The procedure needs to be done carefully because setting up a flywheel on the lathe is not an easy job. The downside of this method is that uneven areas are left.

Since brake lathe skips over hard spots, people prefer removing a large amount of metal. When you want to know ‘how to resurface a flywheel,’ you need to know about both cutting and grinding techniques.

When it comes to vehicles with hydraulic linkages, bearings might be limited. It is imperative to understand that the clutch tends not to release fully when too much metal is removed.

SEE MORE:

Grinding the Flywheel

It is the most preferred technique for resurfacing flywheels. A block grinding machine is required to perform the task effectively. As compared to the dedicated flywheel grinder, grinding equipment for heads and blocks require high setup time.

Make sure to check whether a machine shop has a dedicated flywheel grinder for a stepped flywheel. If not, then look for another shop that has a specific type of equipment for the job.

Maintaining the proper clutch height becomes whimsically essential in the case of a stepped flywheel.

One must ensure to shave off an equal amount of metal from both surfaces. You can measure it with the help of a flywheel depth gauge.

For achieving the necessary flatness with least metal removal, a dedicated flywheel grinder works effectively by removing hard spots and leaving a homogeneous surface. This process generally takes hardly five minutes.

In the process of knowing how to resurface a flywheel, equipment becomes of utmost importance.

The crankshaft flange helps to mount the flywheel and center a recessed flywheel. Wet grinding with silicon carbide stones helps.

What About Dual-Mass Flywheels?

In case of BMW, General Motors, and Porsche with a dual-mass flywheel, you need no resurfacing. Replacement becomes necessary when a dual-mass flywheel is worn.

On Ford applications, the process of resurfacing requires removing the bolts and separating both primary & secondary flywheels. The vehicle company, Ford, suggests usage of new bolts at the time of reassembling the flywheels.

For applications, including 7.3L Ford and 6.5L GM diesel trucks, regular one-piece flywheels come in use to replace the costly dual-mass flywheels.

The same clutch is not good for the solid flywheels. In order to strengthen the torque capacity of the drivetrain, they manufacture it by keeping the larger diameter clutch in mind.

What to Consider When Replacing Clutch And Flywheel?

When replacing the clutch, one must replace all the significant parts in the system. From the pressure plate, clutch disc, and release-bearing, everything needs to be replaced.

Pilot bearing or bushing also needs to be replaced in some vehicles. It works by aligning the clutch disc to the flywheel.

It will result in rapid clutch and throw-out bearing wear after wearing out. A severe consequence includes the problem of clutch disengagement.

No indexing of the flywheel’s position on the crank is mandatory when replacing a flywheel on an internally balanced engine.

However, the index positioning becomes preeminent in the case of the externally balanced engine. The technique here is to mark the position before removing and reinstalling the flywheel back on the crank.

This pro tip will help to maintain the engine balance accurately. Mark the flywheel when you are unsure whether an engine is internally or externally balanced. It will help you install it in the exact position as it was before.

FAQs on Car Flywheel

1. How much material should I remove when resurfacing a flywheel?

The amount of material to remove depends on the flywheel’s condition and the manufacturer’s specifications. It’s crucial to consult the service manual or manufacturer’s recommendations for your specific vehicle.

2. Can I reuse a flywheel after resurfacing, or should I replace it?

Flywheels can usually be reused after resurfacing if they meet the manufacturer’s specifications and are within the allowable tolerances. If the flywheel is excessively worn or damaged, it may need replacement.

3. What are the benefits of resurfacing a flywheel?

Resurfacing a flywheel restores its smooth and flat surface, ensuring proper clutch engagement, reduced clutch slippage, and improved overall vehicle performance. It can also extend the life of the clutch components.

4. How much does flywheel resurfacing cost?

The cost of flywheel resurfacing can vary depending on your location and the shop you choose. It’s best to obtain quotes from local automotive service providers for accurate pricing.

5. Can I resurface a flywheel multiple times?

Flywheels can be resurfaced multiple times, but there are limits to how much material can be removed. Excessive resurfacing may lead to the flywheel falling out of spec, requiring replacement.

Check out this video from Station road Rat rods to learn how to refresh a flywheel qiuck, cheap and easy!

Final Notes

A car flywheel is an essential part of automobiles. Considering the above information, you are greatly benefited in the pursuit of knowing how to resurface a flywheel.

Seeking the help of a professional is highly recommended if you are a beginner or haven’t done the resurfacing of a flywheel before.