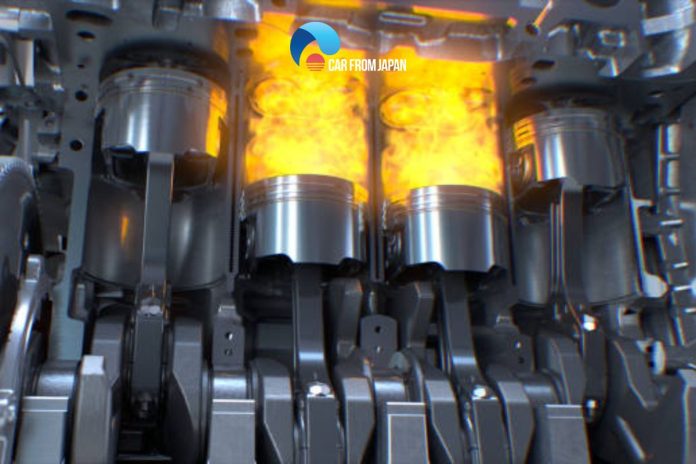

Well, that sputtering sound. Your engine is shaking like it’s about to stall. An engine misfire can ruin your day. But before you panic and call a tow truck, know this: figuring out and fixing a misfire is often something you can do yourself. How to fix an engine misfire effectively? This guide will walk you through the usual suspects behind engine misfires and show you how to find and fix the problem.

Contents

How To Fix An Engine Misfire

Repairing an engine, simple or complex, all depends on the cause. There are common reasons for engine failure: worn spark plugs, weak fuel injectors, vacuum leaks, worn valve seals, or dirty fuel filters. In addition, another reason that counts is the lack of lubricating oil on some models of Japanese and Korean brands. In these cases, you will likely have to take your vehicle in for an overhaul.

However, if you have a good understanding of the basics of automotive machinery and can detect where the problem lies, you can learn and perform the misfire engine repair at home, by yourself, with the right tools.

The engine is fail-ignited usually due to the influences of a few factors mentioned above, such as ignition, fuel supply to the cylinder, or insufficient compression pressure. You need to check those factors from the highly suspicious ones to have the most suitable and timely solution.

With that said, here are a few notices that show how to fix an engine misfire effectively when done on a non-professional scale. Let’s have a look.

Check the cylinders

When encountering an engine misfire, you must first check and determine if the cylinder is working or not. You can do it using a diagnostic machine or by removing the high-pressure lines from the spark plug one by one.

Then observe the engine vibration when it fires. When one cylinder is not working, the engine will be unbalanced, so when it explodes, there will be strong vibrations. We, in turn, remove the high-pressure wire of each cylinder and observe.

If when unplugging the high-voltage wire but the engine vibrates more strongly, it proves that the machine is still working. Conversely, when the high-voltage wire is pulled out, the engine still vibrates and jerks like when the high-voltage wire is not been pulled, it proves that the cylinder is not working.

Note that it is dangerous to disassemble the high-voltage wire when the engine is running. Therefore, to be safe, you should wear rubber gloves and not let the wire ends touch metal objects, or be safer, you can turn off the engine after removing the high-voltage wires.

Diagnose the ignition

First, check the high voltage line to the spark plug, remove the connector with the spark plug, and gently touch the metal surface. In case you hear a tiny click or see a blue spark, it means there is electricity at the end of the wire. If there is no power, it is possible that your high voltage wire is damaged or has a discharge at the distributor cap.

At this phase, remove the distributor cap, check for cracks and high voltage probes and replace them if they are damaged. Note that most ignition systems do not use a distributor, and each coil will control the ignition for 2 cylinders. If the cylinder, due to 1 ignition control coil, does not work, it is a fault in the coil.

If the high voltage wire is still working well, continue to check the spark plug discharge. Remove the spark plug, plug in the high voltage wire, and let the spark plug come into contact with the metal surface.

Then observe, when you see blue sparks and hear small explosions, the spark plug’s discharge ability is still good. If there is no such phenomenon, it shows that the spark plug’s ability to discharge is poor. This issue is a very commonly encountered cause.

Remember that after checking the spark plug, you should also observe the polarity of the spark plug. If there is a lot of black soot, it must be cleaned. If the gap is too large, you should replace all cylinders of the same type.

Check the ignition coil

Next, check your ignition coil, especially if the engine misfires accompanied by a stalling or burning sound. This issue is most common in vehicles aged a few decades old. The ignition coils are usually at the end of your spark plug wire.

Replacing your ignition coils won’t be too expensive. You can find and purchase these parts at most auto parts stores and choose the correct ignition coil for your vehicle make and model.

Check the fuel

After checking that the ignition system works well, the spark plugs still ignite well, proceed to check the fuel supply for multi-point electronic fuel injection engines.

First, start the engine and then put your finger on the injector. If the injector is still working well, you will feel a slight “vibration” at the tip of the finger. Otherwise, it means the injector is problematic or not receiving the electrical signal.

The electrical signal to the injector can be checked by disconnecting the connector from the injector, then inserting a 12V test light or connecting a voltmeter between the injector and the connector to check.

If the engine starts and the lamp does not light or the voltmeter needle does not move, there may be a problem with the wiring or the ECU. If the power is still on but the injector does not work, the injector is damaged. In addition, you can check whether the nozzle is working or not by using a resistance meter to check its continuity.

Sometimes, there is still voltage to the nozzle, and when you put your finger on the injector, you can still feel the vibration. But the injector does not inject or injects very little fuel into the cylinder due to the internal blockage, which is common in low-maintenance vehicles and injector flushing.

Check compression pressures

Coming up next on our notices on how to fix an engine misfire, check the insufficient pressure at the end of the compression stroke.

Causes of compression pressure drop:

- Open valve (usually the exhaust valve because it has to work at a much higher temperature than the suction valve, so it is easy to burn, pit, and wear quickly).

- Due to the fire of the engine face gasket (usually involving two cylinders next to each other)

- Damage to the cam lugs distorts the opening and closing angle of the valve.

- Excessive wear of the ring increases the clearance between the piston and the cylinder

You should use a compression gauge to check the pressure inside the cylinder at the end of the compression stroke. The measurement is as follows. First, disconnect the high-voltage wire from the spark plug and remove the spark plug.

Then insert the cone of the compression gauge into that hole. Use the starter to turn the engine around 10 to 12 revolutions of the crankshaft. And at the same time, observe the pressure on the dial gauge.

During the measurement, ensure the highest pressure on the surface of the meter is not less than 8 kg/cm2.

Vacuum leak test

Open your hood and look for signs of a vacuum leak. Start the engine and listen for a loud squeal. If you hear that, it can be an indication that your problem has a vacuum leak.

To fix this problem, pinpoint the leak using a spray bottle filled with liquid dish soap. Then spray the dish soap all over the vacuum lines and the intake manifold gasket. Don’t forget the PCV valve if you see bubbles. That may be where a crack or vacuum leak is. You can replace any broken part you find.

Check mechanical problems in the system

Finally, when figuring out the real cause of the misfire and learning how to fix an engine misfire, you may be suffering from mechanical failure. You will have to check the engine’s mechanical parts to make sure that everything is working smoothly.

Check the timing chain or belt and ensure that it is not stretched too much due to frequent wear and tear. You can use the timing indicator while the engine is idling to see if your timing chain or belt is stretched.

You will need to replace it if this is the case. Furthermore, check the intake manifold for vacuum leaks. You can use the soap bottle spray technique described above to locate this leak if it exists.

Wrapping Up On How To Fix An Engine Misfire

We have just gone through some notices on how to fix an engine misfire in the most effective way possible. Be careful with your car’s everyday maintenance. And remember to check for the engine regularly as it is one of the most vital parts of a car system.

For more car maintenance tips, follow Car From Japan.