Fuel injections are responsible for passing the right amount of fuel into the cylinders. Since these fuel injectors work millions of times, they may wear off.

Bad fuel injector doesn’t maintain the fuel consistency in the right amount, and that affects overall fuel economy plus poor engine performance.

Hence one should always check if fuel injectors are receiving the correct voltage or not.

Contents

- Testing Fuel Injector For The Correct Voltage

- What Are The Common Causes For Incorrect Voltage?

- FAQs on Correct Voltage in Fuel Injectors

- Is it possible for a fuel injector to receive voltage but still not fire?

- Why does my multimeter show 12V at the injector but the engine still misfires?

- Can injector voltage vary with engine RPM or load?

- Is checking voltage enough, or do I need to test amperage too?

- What’s the best way to simulate load when testing injector voltage?

- Could ECU software or tune settings affect voltage delivery to injectors?

- Conclusion

Testing Fuel Injector For The Correct Voltage

First, we would start with testing the injector resistance, and then we would check them for the wiring.

You would need a Digital Volt-Ohmmeter (DVOM) or multimeter with ohms setting.

Make sure the engine is off since you don’t need power for this checking. You can access the injectors in the engine or use the manual. There may be a plastic shield that you need to remove to access injectors.

Remove injector wiring harness; if there is a slide lock then you need to remove it first to access the wiring harness.

Now you need the DVOM set to measure ohms. Check all the injectors one by one for their resistance. If the meter doesn’t auto range, set it to the lowest range.

If you have high impedance injectors that are common in cars these days, then the range would be from 12 to 17 ohms.

Low impedance injectors would display you a range from 2 to 5 ohms. You need to repeat this action with all the injectors, and each one of them should have almost similar resistance to each other.

If you find any injector to have a major difference in the resistance, it means that injector needs to be inspected. If you want to find the exact resistance for the injectors, you can search for your vehicle’s repair guide.

The Second Part

In part two, we would test the injector wiring to make sure if everything is connected properly.

In this test, you need to keep the key to the second position that is ON. This way you would receive the battery power without turning on the engine.

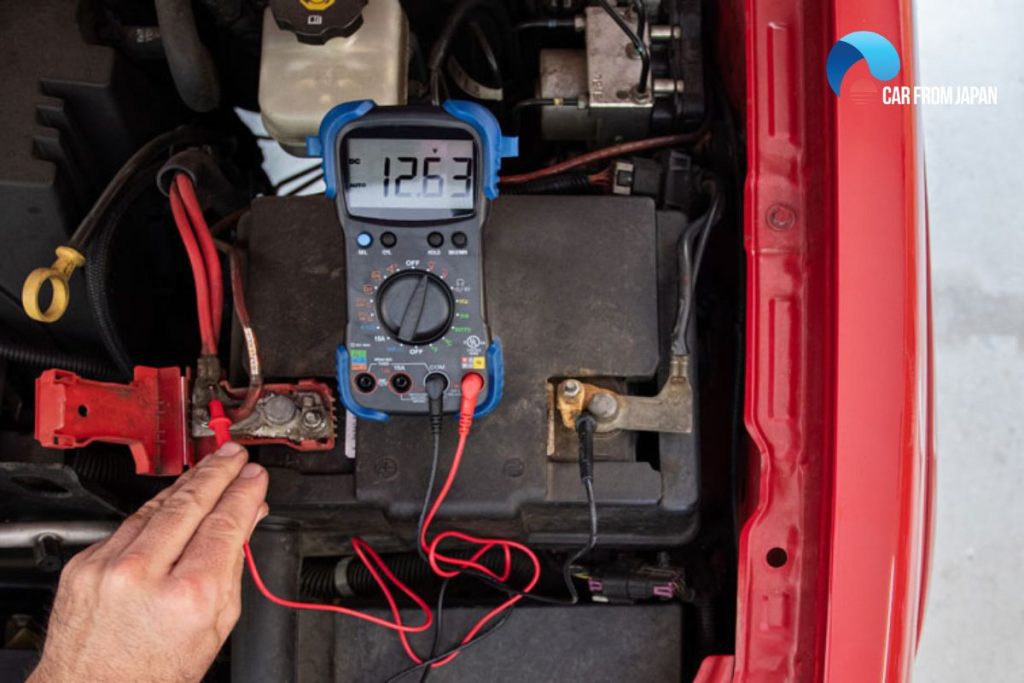

Now you need the DVOM to measure DC voltage, and same as prior, if the meter doesn’t auto range, set it to the lowest.

Take the negative lead of the DVOM and touch it to a ground source. You can look for an unpainted piece of the frame that you can find under the hood. Protect your car against every odd by having these maintenance tips by your side.

Take the positive lead of the meter and connect it to the wiring harness terminal. Upon doing this, one terminal should read 0 volts and the other one as 12 volts or around 12.

While leaving the ground lead in position, you need to test the wiring harness of all the injectors.

If the reading is around 12 volts for each injector, then everything is fine. But if the reading is too low, it means there is a problem in the wiring.

See More: Which Component of a Car Impacts the Fuel Economy Very Much?

What Are The Common Causes For Incorrect Voltage?

Faulty wiring/connectors

The wiring and connectors in the fuel injector circuit are vital for delivering the correct voltage.

Damaged wiring, such as cuts, fraying, or burns, can interrupt the flow of electricity, leading to reduced voltage at the injector or a complete loss of power.

Loose connections at the injector or other points in the circuit can cause intermittent issues, resulting in erratic injector behavior.

Corroded terminals increase resistance in the circuit, reducing the voltage available to the injector and potentially causing performance problems.

Bad relays or fuses

Relays act as electrical switches that control the flow of power to the fuel injectors. A faulty relay can either fail to supply power at all or cause intermittent power delivery.

Fuses protect the circuit from overloads; a blown fuse completely cuts off power to the injectors.

To test a relay, you can swap it with a known good relay or use a multimeter to check for continuity across the appropriate terminals. Fuses can be visually inspected for a broken filament or tested with a multimeter.

ECU problems

The Engine Control Unit (ECU) is the brain of the engine management system. It controls the timing and duration of the electrical pulses sent to the fuel injectors.

A malfunctioning ECU can send incorrect signals, leading to a variety of issues, including improper injector voltage, incorrect fuel delivery, and poor engine performance.

Diagnosing ECU problems often requires specialized diagnostic equipment and expertise.

Low battery voltage

The entire electrical system, including the fuel injectors, relies on a stable voltage supply from the battery.

A weak or failing battery can cause a drop in system voltage, affecting the performance of various components.

In the case of fuel injectors, low voltage can lead to insufficient power for proper operation, resulting in poor fuel atomization, reduced engine power, and difficulty starting.

FAQs on Correct Voltage in Fuel Injectors

Is it possible for a fuel injector to receive voltage but still not fire?

Yes. Injectors require both proper voltage and a clean ground signal (pulse) from the ECU. Voltage alone doesn’t guarantee operation.

Why does my multimeter show 12V at the injector but the engine still misfires?

Multimeters measure static voltage but can’t detect pulsing or load behavior.

You may need a noid light or oscilloscope to confirm proper injector signal.

Can injector voltage vary with engine RPM or load?

The voltage itself should remain steady (typically 12V), but the pulsing frequency and duty cycle from the ECU will change based on RPM/load.

Is checking voltage enough, or do I need to test amperage too?

Voltage checks are a starting point. If you want a deeper diagnosis (e.g. detecting a shorted or high-resistance injector), testing current draw or using an oscilloscope is more accurate.

What’s the best way to simulate load when testing injector voltage?

Use a test light or noid light. They simulate the injector load better than a multimeter and can show pulsing visibly.

Could ECU software or tune settings affect voltage delivery to injectors?

Not directly. The ECU controls ground pulse width and timing, not power supply voltage, but altered pulse behavior can mimic voltage issues.

Conclusion

If you find an issue either in the first part or second when testing the correct voltage, you should take your car to a professional repairer.

You would be saving huge bucks by getting the fuel injector right that otherwise would be spent on the fuel!