It takes only a little mechanical knowledge to do a brake piston replacement. Plus, you need to have a DIY mentality.

A soft brake could be the result of a lot of factors. It might be that there is air in the brake lines, or the master cylinder is leaking.

In any of these cases, a brake caliper piston replacement is recommended. Using a brake bleeder, you can exhaust the air. By the way, to perform a brake piston repair, you have to follow the steps below.

Contents

- How To Do a Brake Piston Replacement?

- What Is The Brake Caliper Piston Replacement Cost?

- FAQs on Brake Piston Replacement

- Can weather conditions affect the need for brake piston replacement?

- Is there a way to prevent brake piston problems?

- How does the material of the brake piston affect its performance?

- What are the environmental implications of disposing of old brake pistons?

- Is it possible for a brake piston to cause uneven brake pad wear?

- Conclusion

How To Do a Brake Piston Replacement?

Here are tools and materials you may need for a smooth replacement process!

- Ratchet or tire iron

- Car jack

- Wrench

- C-clamp

- Drain pan

- Brake bleeding kit

- Piston kit

- Pliers

- Brake caliper piston removal tool

- Air hose

#1. Remove the Wheel and Raise the Car

Using the tire iron or ratchet, loosen the lug nuts and lift the cat using the jack. Use of the jack stand to secure the position and dismantle the tire and the lug nuts. Now set them aside.

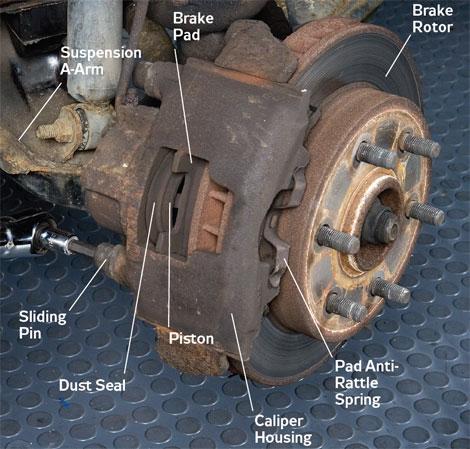

# 2 Remove Brake Pads and Caliper

Get rid of the retaining clips that hold the pads to the caliper. Then, detach the pads from it.

To take out the caliper, push the brake pistons to the rotor, compress the brakes. As soon as the pressure is off, remove the caliper.

# 3. Remove the Pistons from the Caliper

In the purpose of completing a brake caliper piston replacement; remember to prevent one of the pistons from moving while removing the other.

Once you have secured a piston, use a pressurized hose to blow out the other one. Use a rag to wrap the caliper before blowing out the piston, to avoid brake fluid from scattering.

# 4. Clean Up / Brake Piston Replacement

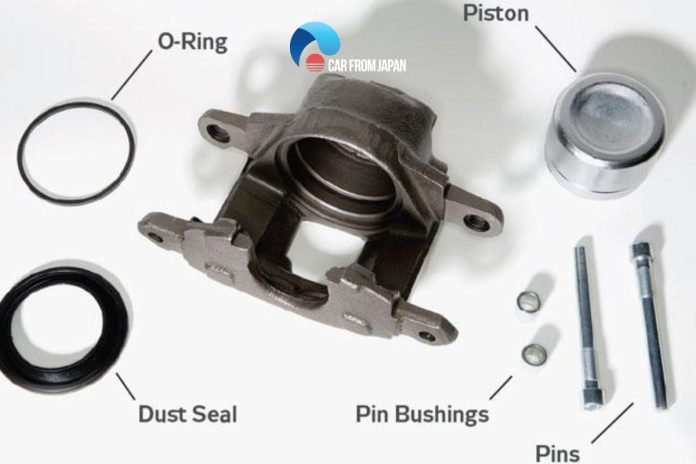

The next step in brake piston removal is cleaning up the caliper. There is a seal in the piston kit for the piston cylinder, along with a retainer pin and rubber dust boot.

Also, replacement retainer clips are there to keep the pads attached to the caliper. You have to replace these parts. Often you may have to clean the pistons as well.

# 5. Reattach Caliper

As soon as you are done cleaning the pieces, put back the pistons and other new parts on the caliper. The piston orientation must be in accordance with the rotor.

The cut out area on each piston indicates the proper way of reassembly. As you make the final adjustment, remove the pads to ensure that pistons compress towards the rotor. To avoid spongy brakes, leave enough room so that you can put the pads.

Though it is quite challenging, once you have done it, it should get easier for you. Bleed the brake cylinder completely after finishing the replacement work and refilling the master cylinder.

What Is The Brake Caliper Piston Replacement Cost?

The cost of the brake caliper piston boot replacement can vary but on average, you may need to pay from $150 to $400 per wheel for parts and labor.

This cost range accounts for the vehicle type, the quality of the replacement parts and the labor rates. Some mechanics will offer a lower hourly rate but take longer, while others might be more efficient but charge much higher.

The piston may be from $10 to $50, but the overall cost comes from labor and associated parts. When replacing a piston, it’s often recommended to replace the caliper’s rubber seals, dust boots, and sometimes the caliper if corrosion or damage is extensive.

Before the replacement, you can consult from reputable mechanics to find a fair price for this safety repair process.

FAQs on Brake Piston Replacement

Can weather conditions affect the need for brake piston replacement?

Yes, extreme weather conditions can accelerate the wear and tear on brake components, including the piston.

In very cold climates, for example, moisture can freeze inside the caliper, potentially causing the piston to stick.

Conversely, in very hot climates, the increased temperature can contribute to the degradation of the piston seals, leading to leaks or sticking.

Is there a way to prevent brake piston problems?

Regular maintenance and inspections are key to preventing brake piston issues.

This includes checking brake fluid levels and quality, as dirty or low brake fluid can lead to caliper and piston malfunctions.

Additionally, avoiding aggressive driving habits that cause excessive brake heat can help extend the life of your brake pistons.

How does the material of the brake piston affect its performance?

Brake pistons can be made from various materials, including steel, aluminum, and phenolic (a type of plastic).

– Steel pistons are durable and resist high temperatures well, but they can be prone to rust.

– Aluminum pistons are lighter and help dissipate heat faster but can wear more quickly.

– Phenolic pistons, while not as heat-conductive as metal, do not expand as much under heat and are resistant to corrosion.

What are the environmental implications of disposing of old brake pistons?

Disposing of old brake pistons, especially those made from metals, can have environmental implications if not done correctly.

Phenolic pistons, however, must be disposed of according to local regulations for plastic waste, as they can release harmful chemicals if incinerated.

Is it possible for a brake piston to cause uneven brake pad wear?

Yes, if a brake piston becomes stuck or fails to retract properly, it can lead to uneven brake pad wear.

One pad may wear down faster than the other, leading to reduced braking efficiency and potentially causing the vehicle to pull to one side during braking.

Check out this video from Fast Fix for more information on rebuilding a brake caliper!

Conclusion

Replacing a brake piston is a detailed process that requires careful attention, the right tools, and a solid understanding of brake systems.

Whether you’re a seasoned DIY mechanic or a novice willing to tackle car maintenance tasks, it’s essential to approach a brake piston replacement with caution due to its critical role in vehicle safety!