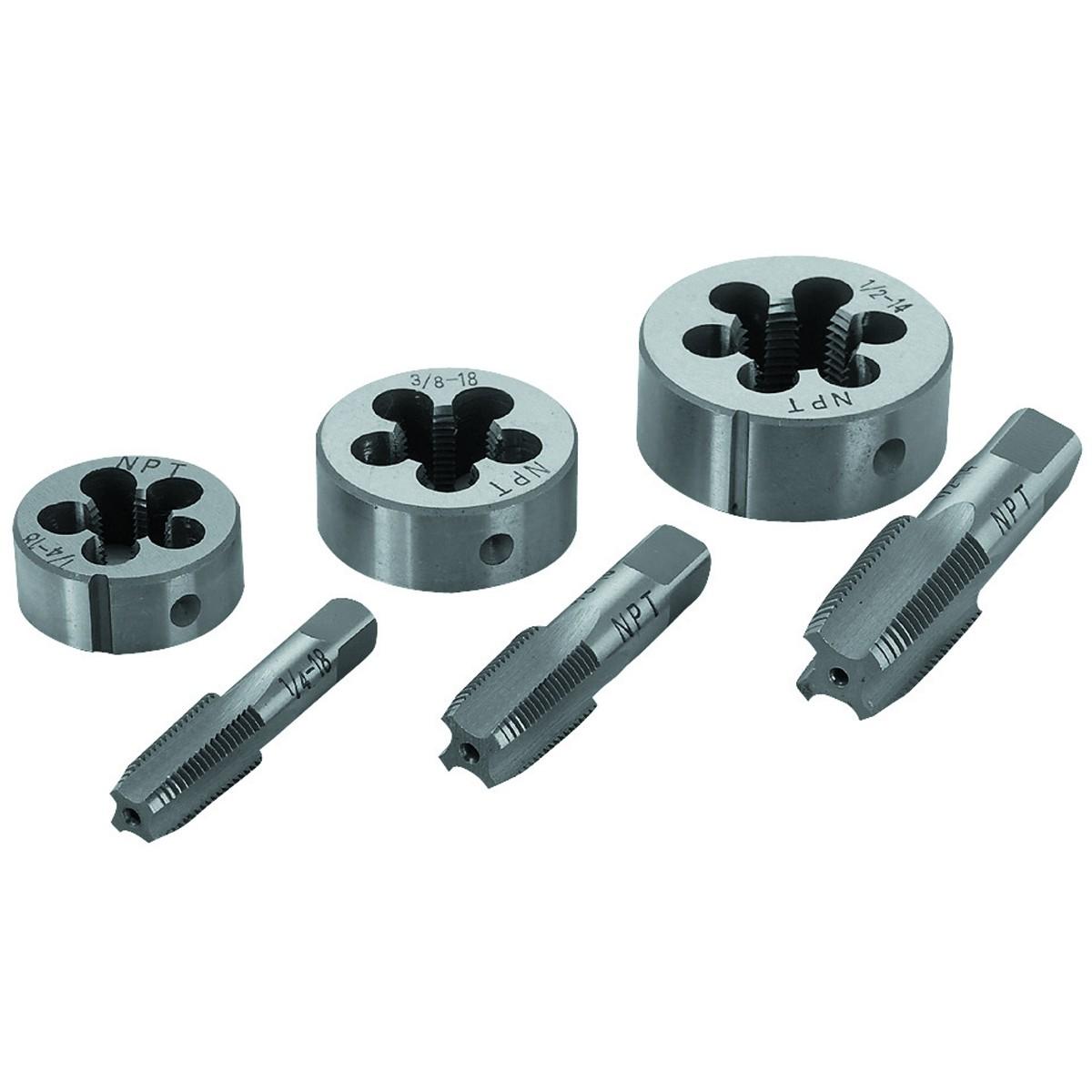

A die tool combinedly refers to two types of tools – taps and dies. They are used for cutting or forming screw threads. It’s called tapping when a tap is used for the process while using a die will give it the name of threading.

A die tool is often used for repairing the damaged threads of a screw. However, it’s better to replace the bolt or screw of its shank is bent or cracked.

Contents

How to Use a Die Tool

A die looks like a nut, the diameter, and pitch of which are matched to the thread of the screw that you will repair. Let’s check out a couple of uses of a die tool:

Repair Damaged Screws

Set the die on the screw by placing the tool’s threaded opening on it. Turn the device with your hand into the direction of the threads to engage it properly with the screw. Turn the device with its handle or a wrench so that it cuts through the threads.

Do a couple of turns clockwise and then the next few in anti-clockwise motion so that metal chips don’t get stuck with the grooves. You may use cutting oil to lubricate the screw and make the turning process easier.

[efsbutton class=”btn” style=”” size=”” color_class=”” align=”left” type=”link” target=”false” title=”Join our FREE CAR GIVEAWAY Campaign here” link=”https://carfromjapan.com/campaign/car-from-japan-free-car-giveaway-2018″]

Make Brand New Threads

The die tool is an excellent device for creating fresh threads on an old bolt. You have to use a vise to grip the bolt firmly and use cutting oil to grease the threads. The use of oil will also reduce the heat that is supposed to be the byproduct of cutting a metal object with metal.

Start turning the wrench over after positioning the die tool on the bolt. After a few turns, rotate the wrench to the opposite direction about half a turn. It will help in cutting the threads even better. Keep turning the wrench until the entire bolt comes out through the die hole. You can use the oil whenever you feel the wrench is not rotating smoothly.

Make a Bolt from a Steel Rod

The tool is also useful in making a bolt or screw out of a regular steel rod. However, you have to collect a beveled end rod to do this because the die tool won’t cut properly if it has a flat end.

Engage the die onto the steel bar and turn the wrench to create threads onto it. Turn the wrench slowly and use cutting oil frequently. It’s a time-consuming process, so you have to have the patience to get the final result.

So, by using a die tool correctly, you can quickly fix the threads of worn out or damaged screws and create new bolts out of a single rod.