Top Materials Used In Cars

Us car owners drive our cars every day and most know about the important car parts, such as the engine, transmission and cooling system. But few of us ever take time to think about the raw materials that go into the making of a car. While the question “What are cars made out of?” might sound naive, the answer is both practical and interesting. There’s a lot to learn about the common materials used to manufacture the main bodies as well as different parts of automobiles. This industry knowledge would allow for a better understanding of the pros and cons of cars made from different materials, and appreciation of what your car is made out of.

What Car Bodies Are Made From

To the question “What are cars made out of?”, many folks might answer “mostly metal”. While this is true, it’s more complicated and fascinating than that. The manufacturing of automobiles uses a vast variety of metals, including steel, aluminum, copper, steel, iron, lead, as well as other materials like plastic, glass, rubber, and even petroleum products.

These materials are used to create everything from the main body of a car, to major parts like the engine block or the transmission gears, to those small things such as the dashboard. Different materials have different properties and are most suitable for the making of different components, or a car with different major selling points.

In addition to their properties, such as weight and durability, automakers have to take many things into consideration to decide which component to make from which material, such as availability and manufacturing cost of a certain material. For instance, some are relatively abundant and cheap to obtain or cheap to form, while others are rare or are energy-consuming and expensive to produce. The goal is to find the right combination of materials for the safest, most fuel efficient, durable and aesthetically pleasing vehicles.

As simple as the name of a material like glass might suggest, the materials used in car production have greatly evolved over time thanks to advancements in automotive manufacturing technologies. They have become increasingly more heavy-duty, safer, more durable and cheaper to produce, and they’re used in increasingly innovative ways.

Below are the most common materials used in automotive manufacturing for the biggest components or structures of a car. We’ll start with the materials used to make a car’s body, then other materials used for making other major parts.

Steel

Steel is an alloy of iron and carbon containing less than 2% carbon and 1% manganese, plus small amounts of sulfur, phosphorus, silicon, and oxygen. For the last 100 years, steel has been by far the most common material used to make the body of the typical car. This is thanks to their heavy-duty property, also they are easy to form by tools like stamping presses, which means they are relatively inexpensive..

That’s why most mass-produced consumer vehicles have bodies and chassis made from steel, with the second most common material being aluminum. Both are strong, but steel is cheaper than aluminum, so is used on affordable cars made for consumer use. Virtually every car on the road is made primarily out of steel.

In addition to the bodies and chassis of an automobile, steel is also widely used in the making of wheels, engines, electric motors, suspension components and exhaust parts. In addition to its use in the automotive industry, steel also has a wide application in engineering and construction. It is used in everything from ships to buildings to consumer products like home appliances to industrial products like healthcare equipment and surgical tools. Steel can be said to be one of the world’s most versatile and important material.

Aluminum

Aluminum is an element, and it is stronger than steel while being lighter by weight. Another major advantage over steel is that aluminum does not rust, and so is used for luxury vehicles as well as performance models. This is because its lightweight characteristics means a lighter car, which results in better fuel economy and reduced emissions. These immense benefits make aluminum a fast-growing rival of steel in the field of car manufacturing.

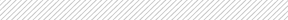

Back in the days, aluminum was only used in exotic cars. However, over the past decade, aluminum has significantly gained popularity as the ideal material for making the body of an automobile. Also, today, many mass-produced cars have aluminum hoods, doors, and trunk lids. Aluminum is also more widely used as an engine block material, and is replacing the conventional material cast iron in many mainstream models.

READ MORE

- Body On Frame Vs Unibody Construction: Key Differences

- Understanding The Automotive Car Chassis System

Titanium

You might not think of titanium when it comes to car materials, since titanium and its alloys are expensive, due to the lack of newer and cheaper methods of mining. This is why most automakers today still refrain from using it in their manufacturing process, and if they do, the material is mostly used in internal combustion engine components, such as valves, valve spring, retainers, and connecting rods. This is because titanium is strong, has excellent resistance to high heat, corrosion and oxidation as well as low density and low modulus.

Despite their high price tag, the application of this metal in the automotive industry is understandable, thanks to its many benefits.

In addition to engine parts, titanium is also viewed as an excellent material for cars body frames because of its strength, lightweight and anti-corrosion properties. Its light weight means considerable improvement in a car’s performance and fuel efficiency.

A few automakers have started to use titanium in major metallic parts instead of the traditionally used steel and aluminum. Regarding titanium bodies and chassis, the purpose is mainly aesthetical. The Vulcano Titanium developed by Icona, a Shanghai-based design firm with Italian roots, was the world’s first supercar concept boasting a unique titanium and carbon fiber body. You can only have it for $2.78 million though.

Magnesium

Another common metal used to make the body, structure, and some engine parts in cars is magnesium ever since 1930. Compared with the two most common materials for the body and chassis, magnesium is 75% lighter than steel and 33% lighter than aluminum. It is also very strong for its weight. However, it is only used in small areas so as to balance the weight distribution of a vehicle.

Fiberglass

While many folks think that glass and fiberglass are the same, they are different. Fiberglass is made mostly of air and the remaining is thin strands of glass that have been melted down, hence the “fiber” part in its name. It is strictly not glass, but essentially plastic reinforced by glass strands. Glass is more solid and heavier, while fiberglass is glass woven together with a lot of air in small sheets, so fiberglass is much lighter.

Fiberglass is also different from carbon fiber. While fiberglass is made of tiny strands of glass, carbon fiber is made of tiny strands of carbon atoms. Both can then be combined with an epoxy resin and pour into molds to create a harder end product of any chosen shape.

In automotive production, fiberglass is commonly used in the roofs, doors, wheels, front bumpers and casings, and in the body of many models. These are areas where steel can get easily corroded, and where fiberglass can effectively replace steel thanks to its non-corrosive property. Fiberglass is used in these parts because it’s fireproof, which allows drivers and passengers to safely get out of the car in case of accidents.

Plastic

This might sound surprising to many, but plastics have become an increasingly common material used in modern car manufacturing, due to the constant drive to maximize fuel efficiency. Many models come with a body that is entirely made from plastic, such as the Chrysler CCV. The purpose is to achieve optimal fuel economy. Plastic is also easy and cheap to produce, and it doesn’t cost much to repair plastic body panels. This material is also easily recyclable, when the car meets the end of its life.

The term plastics actually refers to a wide variety of synthetic or semi-synthetic materials made from different natural resources using different manufacturing processes, and their applications are also enormous and ever-expanding. Plastics used in the making of cars are typically produced from coal, crude oil, natural gas, salt, and cellulose.

Nearly all the soft- and hard-trim pieces in most mass-produced cars on the road today are made from plastics. Plastics of one type or another are also commonly used to make the fuel tanks, and especially the interior or the cabin of an average car, including the dashboard, infotainment displays, consoles, seat padding, armrests, and much more. Even the leather seating surfaces are typically coated with a thin film of plastic for added durability. In addition, thanks to technological advancements that allow for more versatile and sophisticated types of plastics with superior characteristics, many parts that previously would have been made of metal are now made of plastic in many vehicles, including various engines and drivetrains components.

Other Materials Used in Car Manufacturing

Metals

Thanks to its exceptional ability to conduct electricity, copper is commonly used in car manufacturing and primarily in electric motors and electrical wiring. In addition to automobile applications, this shiny, reddish element is in fact the third most used metal for industrial applications, as well as being one of the most-used metals in consumer products. It has been around for tens of thousands of years, and is one of the very first metals that our ancestors encountered and worked on to create a variety of tools necessary for survival.

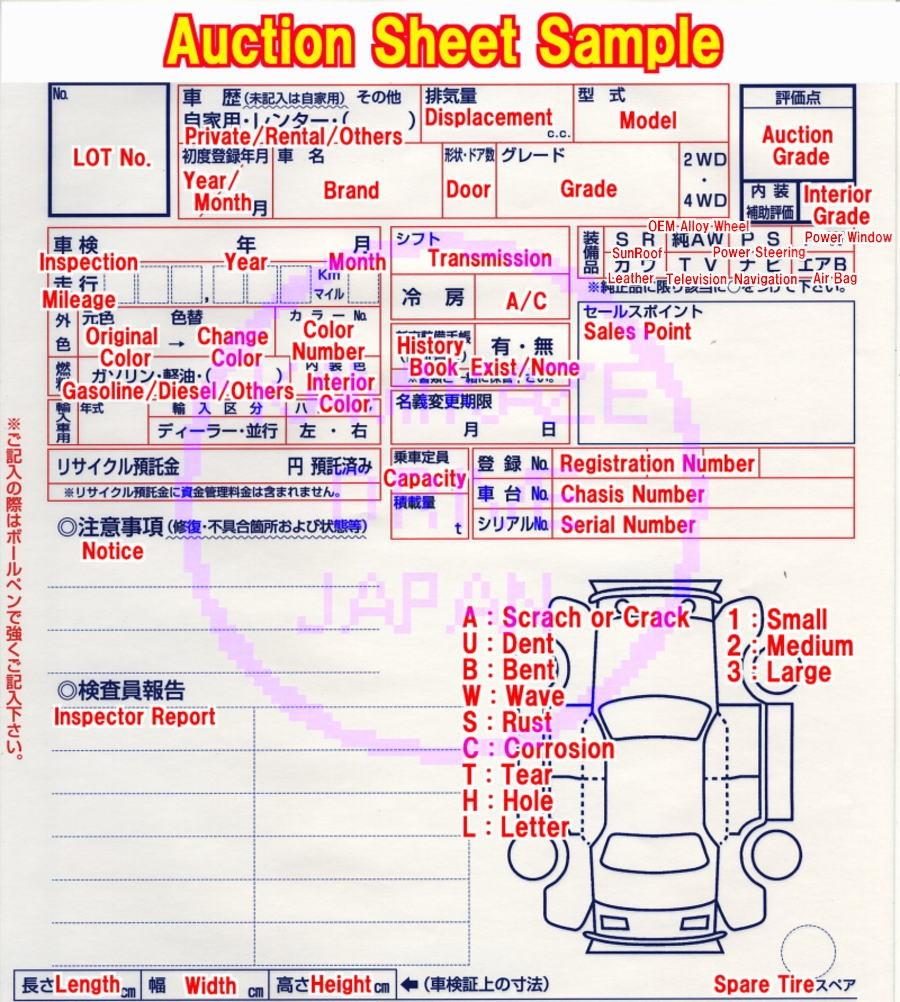

Other metals often used in the making of cars is lead, which is mostly used in lead-acid batteries. Others include palladium, platinum, and rhodium — you might not have heard of them, since they are rare and expensive metals primarily used in catalytic converters, an exhaust emission control device that reduces toxic gases and pollutants in exhaust gas.

Carbon Fiber

The advantages of carbon fiber as a material for car parts is that it’s very light and very strong for its weight. It’s highly rigid, with an extremely stable structure. This means that carbon fiber car parts can absorb quite a lot of physical impact, and when used in the right places, carbon fiber parts make a car safer.

Carbon fiber is often used to make parts that contribute to a vehicle’s aerodynamics, including bumpers, spoilers in front of the tires to reduce turbulence, grille and fascia openings and more. On cars, it is often combined with plastics (forming a composite) for reinforcement, or combined with ceramic to make brake discs.

Carbon fiber parts are strong but weigh considerably less than those made from steel or sheet metal. The light weight of this material means that it can enhance the vehicle’s aerodynamics, fuel efficiency and velocity as well as reducing drag without adding extra weight. The downside is it is expensive, so today it’s primarily used in high-end sports and racing cars.

Rubber

Rubber must be on the list, since they are used to make tires. Interestingly though, while rubber doesn’t seem like a very cool, sophisticated material, over 200 “ingredients” are combined to make a tire that has the capacity to enhance a vehicle’s safety, fuel efficiency, and performance, all the while being earth-friendly.

The tread layers are made from natural rubber, while synthetic rubber is used to strengthen the tread and provide added wear. Meanwhile, what gives a tire a core, or in other words, creating a stable shape and rigidity, are metal and textile reinforcement cables.

Many more “ingredients” are involved, for instance, carbon black and silica go into the making of tires for extra durability. Other chemical agents are typically combined to add on unique properties like better traction or less rolling resistance.

One problem with rubber tires is that even if they just sit there in storage, they still age and deteriorate. Direct exposure to UV breaks down the oils and chemicals in the tire, which keep the rubber flexible and durable, thus speeding up the aging process. To slow down the aging process to some extent, antiozonant chemical compounds are incorporated into the rubber. They are a type of additives for plastic and rubber, which prevent cracking on plastic and rubber materials caused by the tiny amount of ozone in the air, thus their name comes from “anti” and “ozonant”. These tires are often rated for higher mileage.

READ MORE

- How Long Do Tires Last And How To Make Them Last Longer

- How Often Should You Rotate Your Tires & Rotation Patterns?

Glass

Just one look at a car and you can tell that glass is an important component, since you need to be able to see your surroundings clearly to drive safely. Windshields, side windows, rear window, interior mirrors and rear-view mirrors all use glass.

Glass is formed by first heating a mixture of dry materials like silica to a viscous state, then is cooled down fast to prevent the melted mixture from forming a regular crystalline structure. Due to the quick cooling process, the atoms are locked in a disordered state between a liquid and a solid with a crystal arrangement. It is solid, but is neither a solid or a liquid, allowing you to see right through it.